The first time I laid eyes on a supercritical carbon dioxide (CO2) extraction machine in 2012, it was love at first sight. Now, almost a decade later, I still catch myself staring at my rig, “Nancy,” an Eden Labs 20-liter Hi-Flo™, and marveling at her beauty. I’m still very much in love with CO2 extraction after all these years, and you should be too.

Supercritical CO2 extractors are the pinnacle of cannabis extraction, the Ferraris of the extraction industry. One machine can produce a host of products—cartridge-ready vape oil, dabbles, highly pure terpene fractions, crude oil, crystalline tetrahydrocannabinolic acid (THCA), and more. CO2 extraction offers industry-leading utility, giving the user a level of control unmatched in any other extraction method. This article will discuss the underlying concepts behind CO2 extraction for type one, THC-rich cannabis, and apply those concepts to real-world examples and standard operating procedures (SOPs).

We are all familiar with carbon dioxide; we consume it as a naturally occurring atmospheric gas every day when we breathe. We celebrate its linear thermal expansion coefficient properties (ΔL = αLΔT) when we pop a bottle of champagne.

It’s ubiquitous in our world, non-toxic, and non-flammable. In the chemical industry, CO2 is considered a “green solvent,” making it one of the safest commercial extraction solvents available to our industry. This safety profile is what initially attracted me to extraction seven years ago. In that time, I’ve earned over twenty awards across multiple categories from dabs to cartridges to beverages, all done on my CO2 extractor “Nancy.” My point is not to brag but to note that while safety is always first, it doesn’t have to be at the cost of quality.

The Science

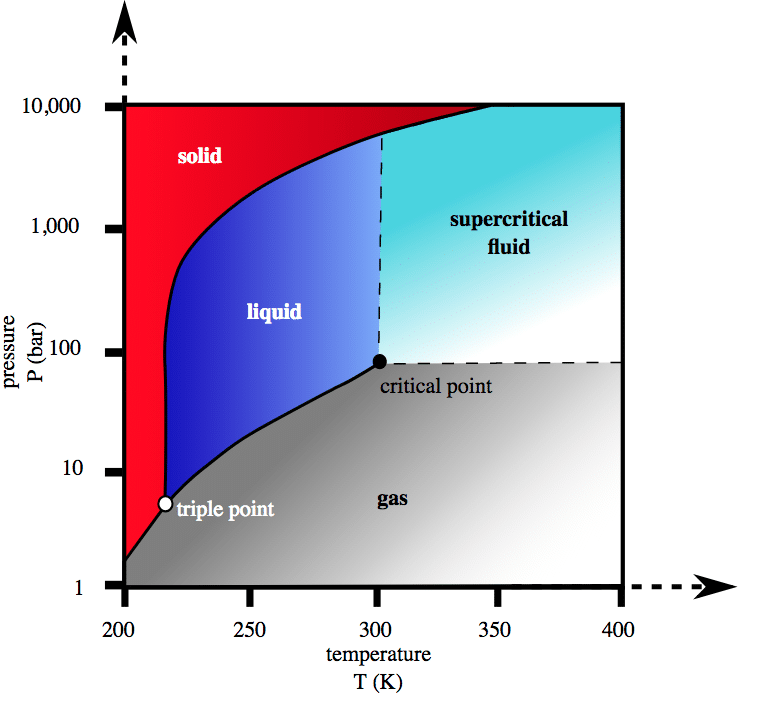

CO2 is a colorless and odorless gas at standard atmospheric pressure. Its phase can be changed by adjusting temperatures and pressures from a liquid (the most commonly used phase in commercial applications) to a solid (aka dry ice) and/or to a supercritical fluid, which is the primary phase used in cannabis extraction.

Figure 1: Phase diagram showing solid, liquid, gas, and supercritical fluid regions for carbon dioxide. (Ben Finney and Mark Jacobs, CC0, via Wikimedia Commons)

Tunability

CO2 extraction is the most versatile method out of any cannabis extraction methods on the market today. Unlike other forms of extraction that are single-phase, liquid solvent systems like hydrocarbons and ethanol, CO2’s phase can be tuned. Like comparing a single-speed bike to a multi-gear bike, our “gears” are turned by adjusting pressures from 900-2000 PSI (62-138 bar) and temperature from <32°F to 120°F (<0°C to 49°C). CO2 can be manipulated from a sub-critical (liquid and gaseous) phase to a supercritical phase that has the properties of both liquid and gas. This offers the operator the unique ability to fractionate in a crude extraction workflow. I call this method of CO2 extraction multi-phase extraction (MPE) and have written and presented on this technique for the past five years.

By manipulating the phases of CO2 between sub- and supercritical, we are increasing or decreasing the affinity of the solvent system for the various compounds of interest. This enables a level of selectivity not found in other solvent systems, whereby extraction of specific compounds from the cannabis matrix can be accomplished without the use of distillation, chromatography, and other organic chemical separation methods. This ability to fractionate is at the core of the MPE method.

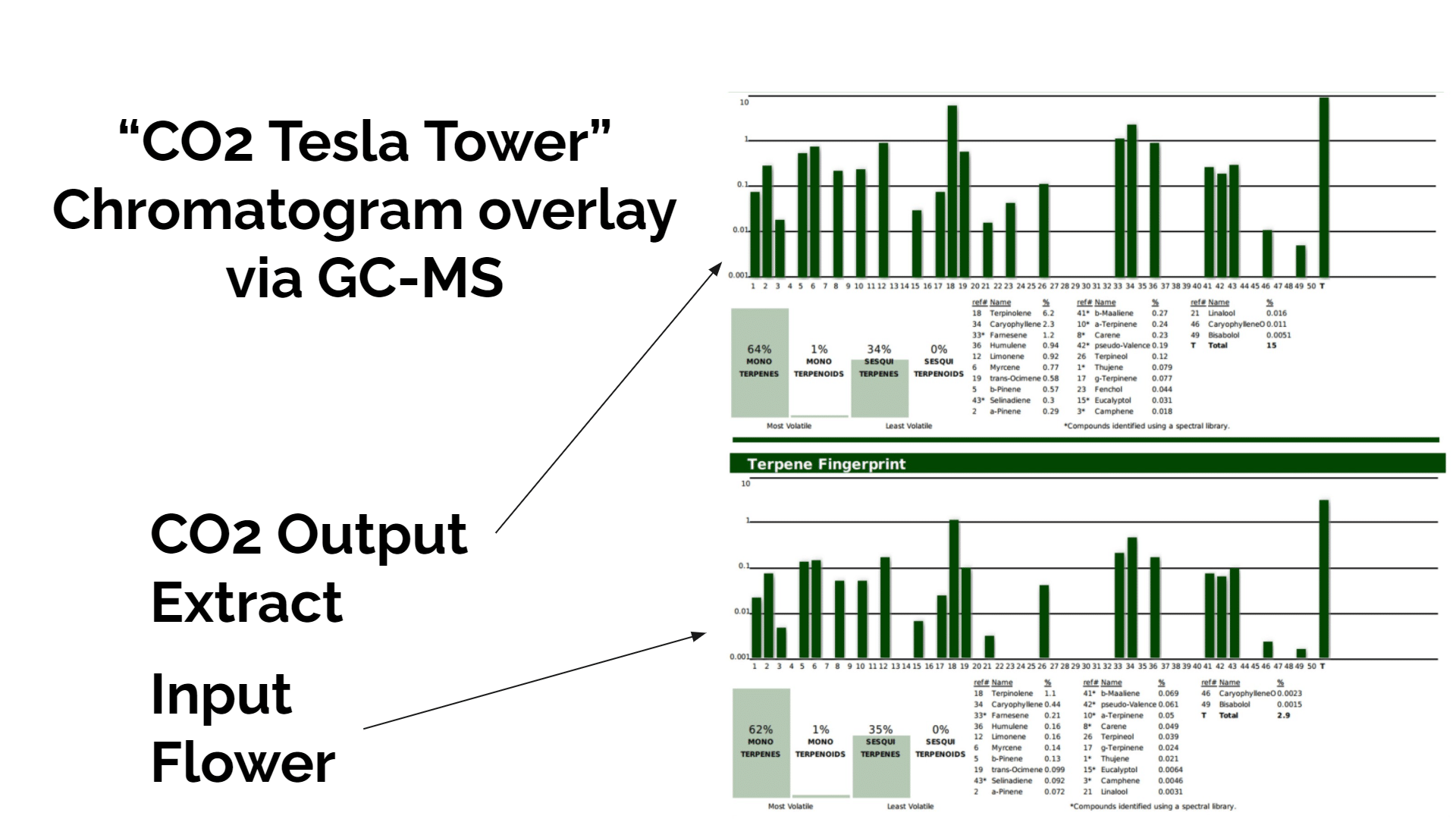

One of the major benefits of the MPE method is its ability to preserve the native terpenoid and cannabinoid profiles as found in the source material and minimize chemovar drift. [1] Chemovar drift is any change in a native cannabis cannabinoid and terpenoid profile from flower to concentrate. This is often the case with extracted products whereby the final extract chemovar is quite different from the starting profile. CO2 done right can preserve native chemovars in full-spectrum products exceptionally well.

Figure 2: Comparison between the terpene profile of a flower and its corresponding concentrate.

There is much irony in this concept; to preserve a native chemical profile in a final extract, one would choose to take it apart piece by piece and put it back together. I thought the same thing when I first started to dive into this method, but the science is sound.

Simply put, the primary compounds of interest to us (terpenoids and cannabinoids) that construct a native chemovar are very different compounds. Cannabinoids are resilient and withstand the rigor of most extraction while maintaining their chemical structural integrity. Terpenes are the opposite, highly reactive, delicate, and fleeting if not properly treated. By “tuning” the CO2 system, we can save delicate terpenes from the intensity required for cannabinoid extraction and marry them back at a later point in the process, ultimately minimizing chemovar drift.

Fractionation

Figure 3: Top: fraction elution sequence from left to right; Bottom right: terpene fractions; bottom left: full-spectrum crude fractions.

How do we fractionate using CO2? We fractionate by adjusting time, temperature, pressure, and flow.

Let’s dive in!

Figure 4: An array of terpene fractions obtained from different cultivars using subcritical CO2.

Fraction 1: The terp fraction, extracted using liquid phase, subcritical CO2.

Cold makes gold. Chill your material and extraction vessel as cold as you can. If you can get below freezing, this is ideal. Steep/soak the column for 10-15 minutes at <1200 PSI (83 bar). Start the closed-loop run at 5 min/kg of material and a higher pump speed. You need to move a lot of liquid CO2 to saturate the material in the column and get a quality terp fraction out. Set separation vessels to 90-110°F (32-43°C), taking care to prevent bumping extract into the recovery/accumulation vessel, which can kill pumps.

Stop the system after the run is complete and harvest the terpene fraction. Every machine is different, and we’ve modified ours to do this fraction exceptionally well. The key is keeping your biomass cold and the CO2 in the liquid phase to keep things flowing with a high pumping rate, but not bumping over extract into the pumping system.

The terpene fraction can be left out at room temperature to degas or be placed in a vacuum oven under light vacuum at room temperature. Depending on how tight the fraction is, it can be used as-is or cleaned up using standard filtration, centrifugation, and/or distillation.

Fraction 2: The THC-rich cannabinoid fraction using supercritical CO2 at 1700-1800 PSI (117-124 bar) at 100-120°F (38-49°C)

Figure 5: THC-rich (left) and CBD-rich (right) fractions (Parameters 1800 psi at 90°F)

Now that the material has been “terp stripped,” it’s time to go for the cannabinoids. I like to run about an hour per kg of material. Run time will vary from system to system. If you’re new to extraction, the best thing to do is to take samples of the material as you’re developing your SOPs and test the material for cannabinoids until you are satisfied with the extraction efficiency versus time. Typically with CO2, you will see about 80-90% of the THC extract in the first ⅓ of a run. It takes ⅔ of the total run time to get that remaining 10-20%, which sometimes is not worth the “squeeze” if you’ve got a lot of material to get through.

If you’re making vape oil, you need THC versus THCA. The fresher the material, the more THCA it has. THCA is great for making dabbles but not good for cartridge oil. It can crystallize and cause a cartridge defect. If you would like to increase the THC oil yield, remove the material after the terp fraction and decarboxylate it in a vacuum or convection oven. Decarboxylating ahead of time makes for optimal extraction efficiency. The key with the THC-rich fraction is timing. You want to stop the extraction before it gets into the THCA fraction. When working in the supercritical range, timing is relative to solvent flow, and the neutral (THC) and acidic (THCA) fractions will elute out based on the above variables of time and solvent flow. Determining when to stop the extraction and pull a fraction depends on the material and the system you are running. Take as many fractions as time allows until you are comfortable with the material and how the various fractions are eluting.

Fraction 3: THCA-rich cannabinoid fraction using supercritical CO2 at >2000 PSI (138 bar) and 120°F (>49°C).

Figure 6: THCA fractions obtained using 2000 psi at 120°F (left) and 1500-1800 psi and 100°F (right).

Pulling crystalline THCA right from the collection cup is pretty cool. But just like making “diamonds” via other methods, the CO2 MPE method takes a lot of “mining” too. First, you need THCA-rich material—the fresher the better. Extracting the terpene and THC fractions prior will make for a cleaner THCA fraction. I like to run about 2-3 hours per kg of material. You will get about 80% of the THCA out this way. The remaining 20% will take 3-4 times as long to extract, so adjust your run times according to your needs. We run overnight, 24/7 to maximize our yields on this fraction, sometimes running almost 100 hours if we are getting good THCA yields.

Post-processing

There are various techniques for post-processing, such as winterization, distillation, media polishing, centrifugation, etc. That said, many CO2 labs can fractionate so precisely that post-processing is not needed. There is no standard way to post-process; some markets like a bright and clear winterized oil while others like it hazier. The professional extractor can execute a variety of finishing/post-processing techniques in order to satisfy the market preference and beyond.

Compounding and Finishing

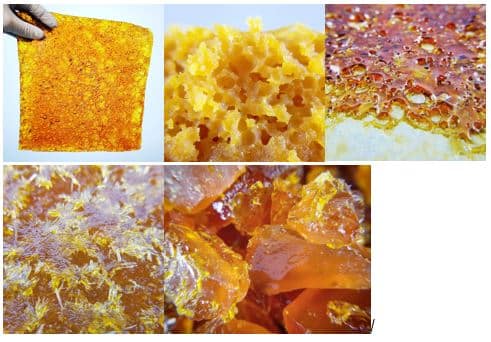

Figure 7: Various “dabable” textures

Once the various fractions are ready for the final formulation, the process for finishing is simple. The oil can be married back (compounded) with the terpenes to create a terpene-rich full-spectrum oil, and/or the terpene fractions can be married back to the THCA fraction to make terpene-rich dabbles. Terpene fractions can be added back at 10-30% by mass, depending on the application. Typically, I like a 10-15% final terpene formulation for cart oil and 10-25% for dabs.

It’s empowering as a formulator when you have the ability to control the ratios of native terpenes to cannabinoids in the final extract. From this point on, the extractor can use typical vacuum oven techniques for dabs of any texture imaginable, from sauce to shatter. THCA-rich fractions make for easy “diamond mining” in pressure vessels and typical organic reagents. THC-rich fractions make wonderful full-spectrum oil and easy 90+ single-pass distillate. This level of control is unmatched in the extraction technology space.

Just like any other piece of equipment in an extraction lab, the true potential is not in the equipment but in the imagination of the operator. There are many types of CO2 extractors, and the SOPs vary from rig to rig. It’s been exciting to see the technology evolve over the years. Inline winterization, inline color remediation columns (CRC), and co-solvent injection are game-changers and further solidify CO2 extraction in the cannabis extraction space. Understanding the fundamentals and capabilities of this process is something all types of extractors could benefit from. The ability to fractionate in crude extraction makes for easy downstream processing, ultimately saving time and money and arguably increasing quality. For that reason, my love affair has never been stronger, and it’s my hope that you find the beauty in this process as I did by diving into the details and pushing the perceived limits of the technology. Happy extracting!

Reference

[1] Reed R. You get the drift: Chemovar drift in concentrates and manufactured cannabis products. Terpenes & Testing Magazine. Nov-Dec 2019.