As cannabis extraction booms, engineers develop new technology to keep pace. Let’s take a quick look at some of the latest cannabis extraction tech products and innovations.

Apeks Supercritical introduced ReFraction, which integrates sensors and software with supercritical CO2 extraction to automate terpene and cannabinoid processing (or alert the technicians). The “smart” technology provides “eyes inside the system,” detecting saturation levels and CO2 in real time.

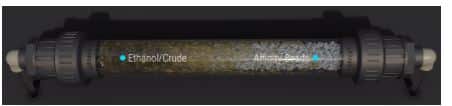

Sixth Wave, a company with extraction experience in the mining industry, launched the Affinity™ to rival legacy chromatography for cannabinoid isolation and purification (e.g., THC remediation). The closed-loop system uses ethanol and Affinity™ Beads (made of unspecified food-grade materials) that capture and subsequently release target molecules.An illustration of Affinity Beads.™ Source: Sixth Wave

Pressure BioSciences brought Ultra Shear Technology™ (UST™) to market with its Baroshear K45, a small-scale instrument capable of emulsifying cannabidiol (CBD) oil for water solubility at 1 liter per hour. The technology works by creating intense shear forces from ultra-high pressure (greater than 20,000 psi). Further commercialization is anticipated.

Linked Equipment and Capna Labs deliver Mobile Hemp Extraction Labs as steel shipping containers equipped for C1D1 or C1D2 operations. The company customizes units based on the desired solvent and extractor’s needs.

Diversey and Advanced Extraction Systems Inc. (AESI) engineered an automated clean-in-place (CIP) system for supercritical CO2 extraction systems. The solution would eliminate the need for manual ethanol cleaning.

Ecodyst brought out their 200 L EchoChyll X9, the largest (per volume) rotary evaporation system in the world. It is designed to meet the “highest volume requirements for decarboxylation and solvent recovery.”

Thar Process introduced industrial scale supercritical fluid chromatography technology to remediate tetrahydrocannabinol (THC), mycotoxins, and pesticides. The cGMP certified equipment is reported to be a “less expensive and greener method than high pressure liquid chromatography.”

United Science, a manufacturer specializing in the pharma, food, and oil & gas industries, designed the DrainDroyd, a stainless steel filtration instrument (cellulose filter paper) capable of handling liters of winterized material within minutes. It’s a little dated compared to the other entries but deserves mention for providing a safer and more efficient alternative to glass.

This is by no means a complete list. Tomorrow will surely bring new tech products targeting specific inefficiencies and needs across the cannabis extraction industry.