The most common industry methods

Calculating extraction efficiency seems like a pretty straightforward process.However, in the case of cannabis extraction, this is not the case.

Each cannabis extraction, or“run” as they’re called in the industry, begins by filling up an extraction vessel with a certain starting mass of plant material. The cannabinoids are extracted from the plant matter using some type of solvent. The loaded solvent is transferred to a collection chamber, where some type of cannabinoid concentration occurs, usually by means of evaporating and reclaiming excess solvent from the sample. The resulting resin is known as the ‘crude extract,’ ‘crude oil,’ or simply ‘crude’.

The process, at this point, diverges depending on whether you are making vape oil or full spectrum extracts. Focusing on the vape oil method, the crude is taken through successive rounds of distillation and winterization to purify and concentrate the desired cannabinoids. Full spectrum extracts do not undergo distillation, but instead are placed directly into a low-temperature vacuum oven, where the hardening and crystallization process can be controlled to create the various extracts on the market.

In the lab, more data is better than less. For the extraction process, there are several key parameters that help describe extraction efficiency. First, determine how much crude oil is extracted from each run with x amount of starting material. On its own, that number doesn’t mean much, because the viscosity of the crude–and therefore its weight–depends almost entirely on operator technique and varies from sample to sample even for runs with equivalent masses of starting feedstock. Another important variable to track is solvent loss during each run. Together, these two numbers can help you calculate the mass of crude oil extracted from the starting material.

This number is useful for tracking employee performance and crude oil consistency, but reveals little about the overall extraction efficiency extraction. The percentage of THC or CBD in each cultivar is of course different. Not only that, but the efficiency of each extraction method, each individual system, and each specific operator are different.Finally, downstream processes such as the distillation, winterization, and filtration stages all effect the final mass of ‘polished gold’. Tracking the mass of every batch as it goes through these stages helps you manage inventory loss. The most important parameter to know, however, is the difference between the final mass of the crude oil and the purified, concentrated oil.

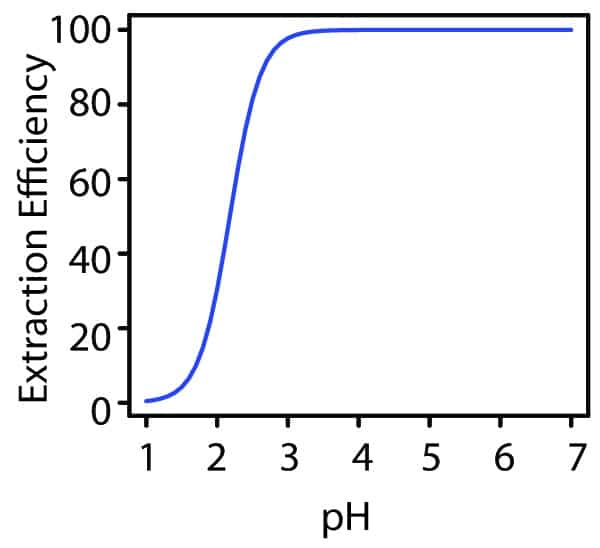

When your product is tested for potency, whether in-house or at a certified laboratory, the batch mass together with the potency concentration will tell you how much THC or CBD is in your batch. From there, you can calculate how efficient your extraction was by comparing the total cannabinoid concentration in the crude oil to the assumed total cannabinoid concentration in the plant, which is given by the percent THCA or CBDA declared on the label or by the cultivator. These numbers can be converted to THC and CBD using respective decarboxylation factors. You will also be able to quantify cannabinoid loss in your downstream processes by figuring out the difference in absolute cannabinoid content between the gold and the crude.

Science might seem difficult from the outside, but in reality, it is just a matter of thinking the process through and working through the problem logically.