Ultrasonic cannabis extraction is somewhat reminiscent of the way you would imagine the Big Bang happened. Its allure lies in the natural laws and mechanical forces it follows, and the end product is a true reflection of this beautiful simplicity.

How It Works

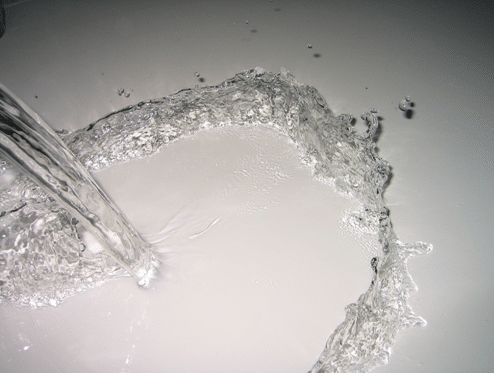

Ultrasonic extraction employs a process called sonication – the use of ultrasonic waves. A probe is inserted into a solvent mixture, and then starts emitting alternating high and low-pressure sound waves. These cycles are extremely fast and can go up to 20,000 times per second. The rapid fluctuations create pressurized streams in the solvent, forming something like a mini sea storm. Millions of microbubbles are born. Low pressure causes them to expand while high pressure makes them implode with ferocious force. The process is called cavitation and is the bubble equivalent of a dying star. The bubbles’ implosions radiate millions of microscopic shock waves which can’t do much alone, but as a whole generate enough energy to disrupt the cell walls of the source material and thus to break off the desired compounds from it into the solvent.(1)

The Benefits

The benefits of ultrasonic extraction span across a very broad spectrum, one that stretches from extractors’ perspective to the one of end users. (2)First off, solvents in this case serve merely as a suitable environment rather than the actual catalyst; therefore harsh solvents are not required. This makes for a purer, toxin-free end product.

Second, it’s simply very fast. The whole thing takes mere minutes, which compared to the hours and even days other methods take, is almost too good to be true. The process can also be fully replicated, meaning that once extractors have found a product they are happy with, making more of it is a matter of repetition.

Furthermore, ultrasonic extraction is very economical and much cheaper than other extraction methods – the required equipment is usually several hundred dollars, with the exceptions costing a couple of thousand dollars. Compared to potential cost-prohibitive, highly advanced technology, ultrasonic extraction provides a reasonably priced alternativethus leveling the playing field and providing small to medium-sized businesses opportunities to produce high quality extracts.

Perhaps the most beneficial aspect of ultrasonic extraction is considered to be its mild, non-thermal nature which prevents the degradation of the extracted active compounds. The best results of ultrasonic extraction are achieved at a temperature between 0-60°C(3) and end products usually carry the same, but intensified properties of the source material – taste, smell, and effects. (1)

Solvents

This is basically another advantage of ultrasonic extraction as it operates with virtually any solvent. However, the choice of solvent depends on the extract’s application. If extracts are meant for inhalation, butane, supercritical CO2,propane and other gases can be used, whereas for oral ingestion, extractors can use ethanol, cyclohexane, isopropanol, olive oil, coconut oil and more. (3)

Overall, ultrasonic extraction is a very energy-efficient, natural, and rather straightforward method to not only make quality extracts, but ones of distinct, calculated quality that can be replicated with pinpoint accuracy. Even though it sounds complicated and highly technological, it actually represents technology’s best use – to give professionals a chance to showcase their actual talent rather than acting as its substitute.

References: