Best Industry Practices for the Preservation and Extraction of Terpenes in the Preparation of Concentrates

Terpenes are hard to capture and even harder to retain. Of the several dozen terpenes identified to exist in cannabis thus far, over 15% of them are considered “light” and may evaporate directly off the plant at room temperature. [1] This and other features causes freshly cultivated flower to quickly lose its full therapeutic effect and concentrates to degrade quickly when improperly stored. So, what are some ways that we can ensure complete capture and retention of our desired terpenes?

Harvest and Processing

Your successful capture of terpenes at this stage is more crucial than any other. Terpenes uncaptured or lost cannot be recouped by any amount of successful laboratory guidelines. It is worth investing in the infrastructure necessary to make this step be as successful as possible.

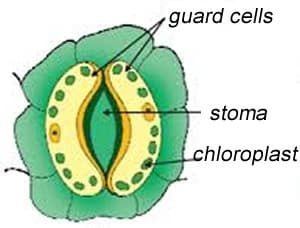

One way that cultivators maximize terpene capture is by early harvesting their crop. Harvesting cannabis before full maturity of the flowers allows for more complete terpene capture because plant stomata are not yet fully-formed on the young cannabis buds. Stomata are special organs present on leaves that open and close to facilitate discontinuous, intentional gas exchange. Less stomata means less gas exchange, so the terpenes inside the plant cells tend to have less ability to escape.

Besides keying in actual time of harvest, flash freezing of vacuum-sealed cannabis immediately post-harvest is the best way to ensure full retention of terpene profile. Similar to the way fish is packaged at sea, vacuum sealing minimizes chemical degradation viaoxygen exposure. It also eliminates exposure to moisture that can lead to molding. Flash freezing, usually done with dry ice in isopropanol (if liquid nitrogen is not available), locks molecules in place on a microsecond timescale, fully freezing afive-pound bag of uncured flower in less than ten seconds. It is the preferred method of temperature reduction as it prevents molecular degeneration (“freezer burns”) caused by ice crystal formation. [2] The sheer difference in temperature between room temperature (commonly 20°C / 68°F) and dry ice (-78.5°C / -109°F) drives the speed of the reaction, bringing materials to sub-zero temps without allowing water enough time to aggregate and crystalize into ice.

Storage

Temperature regulation is the key to successful storage. [3] Always keep “fresh fro” below freezing, especially during delivery or transit. It is vital to ensure that ANY manufacturing equipment that comes into contact with the material has been thermally regulated. Extraction cylinders, hand-scoopers, even surfaces used for breaking apart clumps of bud, all should have been previously cooled by placement in chillers overnight. A walk-in freezer is honestly the best way to accomplish this goal.

Besides temperature regulation, light exposure of frozen cannabis flower must be kept to an absolute minimum, especially during long storage periods. [2] Photons from surrounding light sources can interact with and break apart the fragile molecular bonds of the delicate terpenes, degrading their constituent, active composition. Storage in walk-in freezers, therefore, has the added benefit of keeping ambient light to a minimum as well.

Extraction Conditions

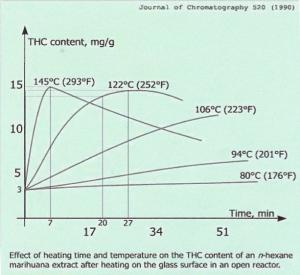

As mentioned before, terpenes can be finnicky compounds. Although the word ‘terpene’ refers to a wide range of molecules, enough of them are delicate (and volatile) that even mild amounts of heat in the extractor will lead to degradation. [1] In addition, exposure to the high pressure, solvents, and mechanical agitation associated with the extraction process can only cause more harm. As the figure below shows, even small changes in extraction conditions can result in dramatic differences in final product composition.

However, as with many things in life, moderation is key. The best terpene extraction procedures will balance internal temperature and residency time to minimize degradation and maximize efficiency, continuously testing the exudate to dial in the extraction method. If methodically done, it will also account for variations in extraction method, solvent, weight/amount of material being run, and the exact cultivar being processed.

Display Considerations

Prevent excessive light exposure by avoiding the temptation of clear packaging, and instead designate a rotating set of not-for-sale “Display items.” As stated before, light equals loss. Cooling displays down, especially if your store or distribution center is located in a hot climate, will undoubtedly make a real difference in preserving your hard-earned terpenes. Consider doing the same for your inventory storage area.

Many cannabis concentrates are made without preservatives or stabilizing agents, increasing the susceptibility of terpenes (and cannabinoids) inside to decay on the shelf. Some companieseven choose to formulate their oils ‘as-is,’ without cutting agents. Without stabilizers, the terpenes in these formulas can come “crashing-out” of solution, separating from the cannabinoids and forming two distinct layers inside the “For Sale” products! It’s quite irreversible once it occurs.

Manufacturing concentrates is a rigorous and expensive process, requiringample time and money to create. Spend a little more of eachto increase the value of both,and your concentrateswill be as freshand aromatic as the bud at harvest.

References

- Jiang, Z, et al. Extraction and Analysis of Terpenes/Terpenoids.CurrProtoc Plant Biol. 2016;1:345-358. [Times cited = 1, Journal impact factor = U/K]

- Barrett, Diana and Lloyd, Beate. Advanced preservation methods and nutrient retention in fruits and vegetables. J Scl Food Agric. 2012;92:7-22. [Times cited = 7, Journal impact factor = 2.463]

- Trofin, Irenne, et al. Long-term Storage and Cannabis Oil Stability. Revista da Chimie. 2012;53:294. [Times cited = 8, Journal impact factor = 1.412]