What is it, and what does it have to do with cannabinoids?

You know what’s an emulsion? Mayonnaise. It’s liquid egg that’s been stirred and beaten until it forms a colloidal suspension. Emulsions are used all around us in our everyday lives. But have you ever heard of nano-emulsions? And what do they have to do with cannabis?

A recent patent filing suggests that particles as small as 50 nanometers (nm) in diameter are achievable for cannabinoid colloidal suspensions. [1] The method that was outlined in the patent goes like this: 1) dissolve one or more cannabinoids or cannabinoid-analogues in ethanol, 2) stir the cannabinoid solution into distilled water, and 3) remove the ethanol from the mixture, leaving behind a “stable, aqueous micelle suspension of one or more cannabinoids.” Interestingly, unlike regular micelles, because the original ethanolic solution contained isolated cannabinoids, the core of the micelles lack oil and fats, allowing them to be smaller.

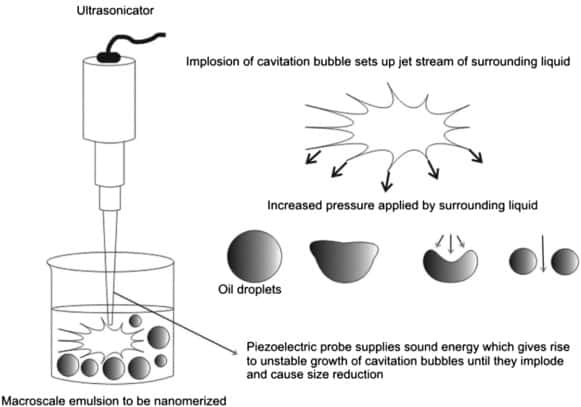

Smaller particles have an easier time crossing into the body through its protective layers of skin or mucus membrane. One way that’s been used to create oil droplet sizes below 100 nm is with the help of ultrasound technology, also called sonication. [2] This method worked best and achieved droplet sizes as low as 40 nm when the geometry of the applied soundwaves was optimized to the molecular structure of the hydrophobic molecules. This is achieved by physically altering the shape (straight-edge, serrated, sloped) of the probe that produces the sound waves.

Sonication has been used to produce nano-emulsions from essential oils such as orange peel. [3] In this process, sound energy at high frequencies is used to break apart particle aggregates by forcing the formation and implosion of tiny bubbles (see figure below). Factors that affected the droplet size in this method include the amplitude of the sound waves, the length of time the sample was subjected to sonication, and the processing temperature. For sound waves, and, in fact, waves in general, the amplitude is equal to the power or strength of the wave, so a higher amplitude means a more powerful soundwave.

Microfluidization is another method that has been used to produce sub-micron emulsions of the terpene limonene. [4] In this technique, a mixture of the oily compound mixed loosely into distilled water is sucked up into a fluid compressor and then shot through a tiny aperture at extremely high pressures. The driving force in microfluidization emulsion formation is the tendency of hydrophobic compounds to stick together. The formation of small droplets is caused by the mechanical agitation, though increasing the pressure above a certain level can lead to a certain degree of re-coalescence. Comparison of these two methods side-by-side reveals that, while both are able to produce nanoemulsions of equivalent size, microfluidizers produced emulsions with a more consistent size distribution. [5]

So why do we care about all of this? Unadulterated cannabinoid bioavailability is low and problematic for a number of reasons [6]. A need has been identified for fast-acting, water-soluble cannabinoid solutions that produce reliable, pharmacodynamic dosing. Nanoemulsions are the way with which we can directly incorporate—and make entirely soluble—these cannabinoids and terpenes that would normally not suspend in water.

References

- Winnicki, Robert. Full Spectrum Laboratories Limited, Dublin (IE). Cannabinoid Formulations. Patent No. US 8,808,734, Aug. 19th

- Leong, T.S. et al. “Minimising oil droplet size using ultrasonic emulsification”. Ultrasonics Sonochemistry. 2009; 16(6): 721–7 [Times cited = 393, Journal impact factor = 1.412].

- Hashtjin, A.M. and Abbasi, S. “Nano-emulsification of orange peel essential oil using sonication and native gums”. Food Hydrocolloids. 2015; 44: 40e48 [Times cited = 45, Journal impact factor = 3.140].

- Jafari, S.M. et al. “Production of sub-micron emulsions by ultrasound and microfluidization techniques”. J Food Engineering. 2007; 82: 478–488 [Times cited = 346, Journal impact factor = 1.279].

- Jafari, S.M. et al. “Nano-Emulsion Production By Sonication And Microfluidization—A Comparison”. Int J Food Prop. 2006; 9: 475–485 [Times cited = 315, Journal impact factor = 1.845].

- Gallily, Ruth, et al. “Overcoming the Bell‐Shaped Dose‐Response of Cannabidiol by Using Cannabis Extract Enriched in Cannabidiol”. Pharmacology & Pharmacy. 2015; 6: 75‐85 [Times cited = 35, Journal impact factor = 2.405].

Image Credit: Born2Invest