Nick Tennant, founder of Precision Extraction Solutions and SVP of Innovation at Agrify

Extracting terpenes from cannabis is a delicate but necessary process if you’re in the business of making and selling products containing extracts like edibles, tinctures, and concentrates. While many companies are only interested in extracting cannabidiol (CBD) or delta-9-tetrahydrocannabinol (THC) from cannabis, using isolated terpenes is another way for companies to reach consumers in search of a specific effect, feeling, or experience. Before being extracted, terpenes contribute to the smell, flavor, and most importantly the pharmacological effects of the plant. After being extracted, terpene oils promote clarity, provide increased relaxation, lower stress levels, and reduce chronic pain, among other therapeutic and medicinal uses. [1] They also combine with cannabinoids to have a synergistic impact on the human body.

So, what’s the best way to extract terpene oils?

Solvent-Based Hydrocarbon Terpene Extraction

Terpenes must be extracted gently at a very low temperature in a way that will not affect the resulting product. Terpenes are sensitive to pressure and heat, and too much of either can ruin the oils’ flavors, aroma, or chemical structure.

We recommend using a light hydrocarbon to extract oil with a high terpene profile, specifically butane or propane or a propane-dominant blend. Harvesting the plant when terpene content is at its highest and extracting it with light hydrocarbons results in a soupy mixture that can then be lightly heated to remove the solvent; the required temperature isn’t high enough to degrade the terpenes. A centrifuge can then remove the terpenes and separate them from the cannabinoids, resulting in a purified terpene compound.

Using light hydrocarbon solvents has become a popular extraction method by cannabis companies in recent years. Hydrocarbon solvents have been used safely by the food industry over the last 50 years, and the method is FDA-approved. Additionally, it’s an inexpensive and very effective way to extract terpenes from plant material.

What the Hydrocarbon Extraction Process Looks Like

Step 0: Assess Quality of Plant Matter

Before beginning any extraction process, one must first ensure that the plant matter being used has been properly cared for. If you want a high-quality product, you need to start with high-quality ingredients. Make sure your plant matter has not been exposed to degrading elements like ultraviolet light, heat, and oxygen. Ideally, you should also be storing your plant matter in a light-free environment with stable temperatures, preferably in vacuum sealed (and nitrogen-filled) bags.

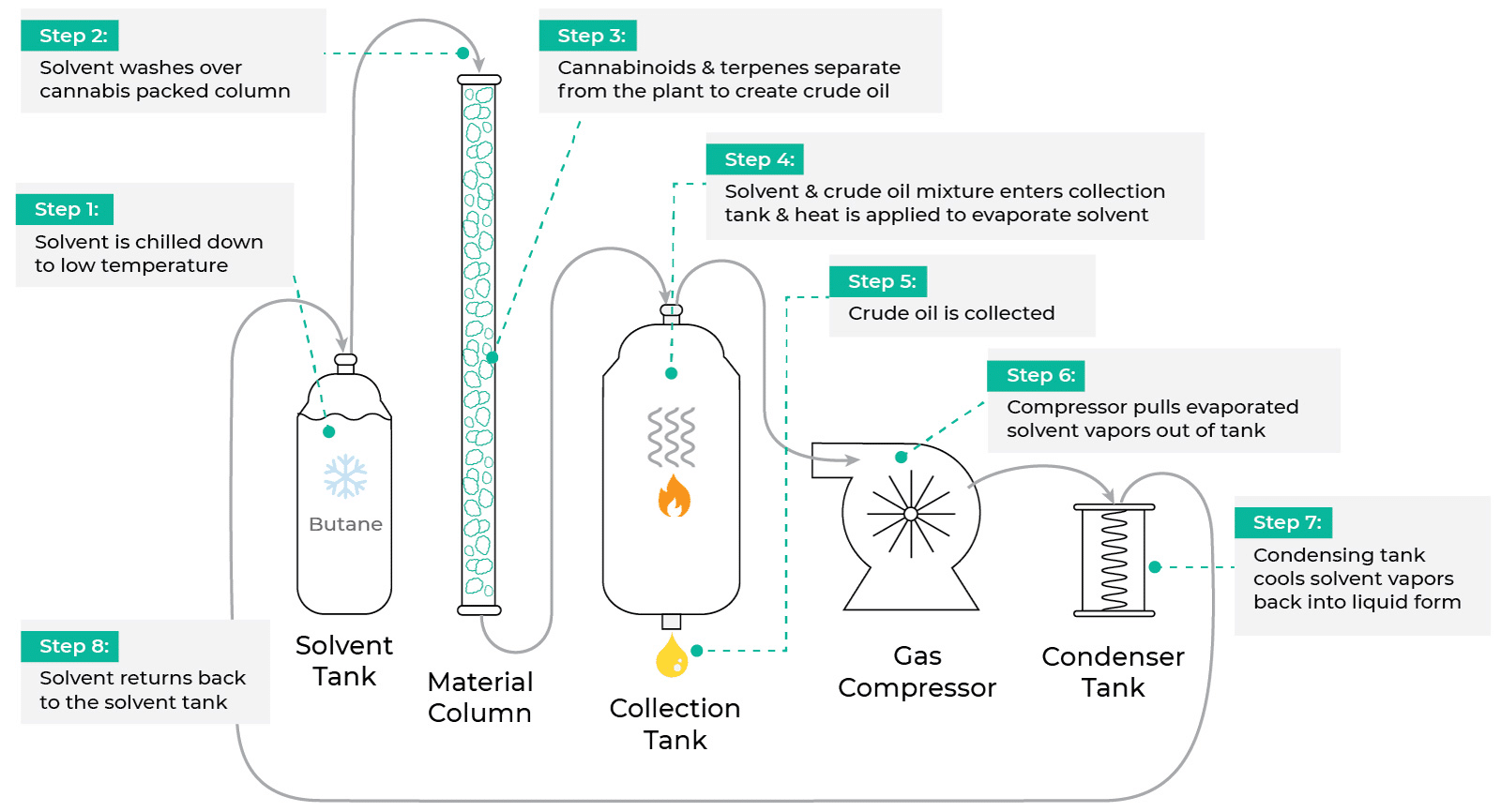

Step 1: Primary Extraction

The first step in the extraction process, primary extraction, involves flushing cold butane through the solvent tank into the material column. This is where the hydrocarbon washes over the base plant matter – dissolving the terpenes and cannabinoids into the solvent. Once the plant material has been washed, the solution can be directly captured, or it can be processed in different ways.

Step 2: Refinement

At this point in the process, a choice of further refinement depends entirely on the desired end product. This could mean using something like in-line de-waxing, where the initial extract is passed through stainless steel beads or another filtering medium to hold back undesired materials.

An alternative and popular refinement technique used in tandem with hydrocarbon extraction is winterization. Winterization uses a solvent such as ethanol at a high ratio to the base solvent. It is mixed with the extracted solution, and chilled to separate each element. This chilled solution then passes through a series of fine filters to separate out the waxes and lipids from the concentrated solution.

Step 3: Concentrate Collection

After refinement, the concentrate solution passes through to the collection pot, and any residual butane is passively removed. This purge moves the isolated butane back into the solvent tank, thus creating a “closed-loop” system. This process repeats until the majority of the butane is removed from the solution — then the concentrate is collected for further separation.

Step 4: Final Purging

There are multiple techniques for purging final solvent levels from the extraction solution. The desired end product will usually dictate which method is chosen — for example, when making shatter, the collected concentrate is spread thinly to expose as much surface area as possible, and is then placed in a vacuum oven over a lengthy period of time (36-48 hours). To separate terpenes from the primary extract though, one would use a centrifugal device.

How Precision® Can Help with Terpene Extraction

Hydrocarbon extraction is a preferred extraction method for many cannabis processors across the world. Our closed-loop, hydrocarbon extraction systems are certified safe and effective for the production of superior terpene oil concentrates.

Reference

[1] Cox-Georgian D, Ramadoss N, Dona C, Basu C. Therapeutic and medicinal uses of terpenes. Medicinal Plants. 2019;333-359. [journal impact factor = 2.63; times cited = 53]