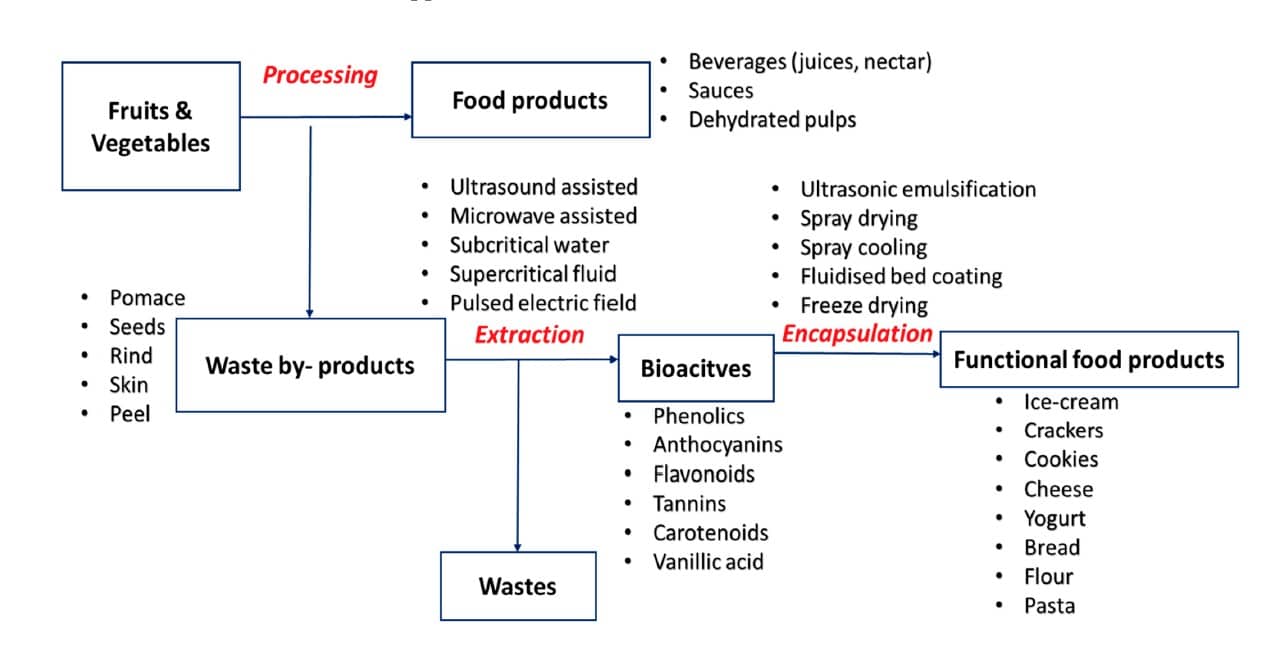

Did you know that between the United States, India, the Philippines, and China, we produce over 55 million tons of fruit and vegetable waste (FVW) every year? That’s a whole lot of waste that could be going to good use. FVW usually consists of roots, bark, seeds, peels, rinds, leaves, and other parts of the fruits and vegetables that are discarded during the processing of food products. [1]

All those FVW products contain beneficial compounds like terpenes, pigments, polyphenols, and other bioactive compounds that are being wasted instead of being up-cycled back into our food supply. This is where extracting beneficial bioactive compounds from FVW comes to the rescue.

A scientific review and analysis of extraction methods being used to collect these bioactive compounds from FVW to use in other functional food products was recently published. The review points out the most common extraction methods including supercritical fluid extraction, subcritical water extraction, ultrasonic-assisted extraction, microwave-assisted extraction, and pulsed electric field extraction. Each of these extraction methods is already in use for extracting bioactive compounds from FVW, but “the demand for extracting bioactives by green technology with no solvent or minimal use of GRAS [generally recognized as safe] classified solvent is increasing… owing to the potential toxicity of some organic solvents, solvents such as CO2 [carbon dioxide], water, and deep eutectic solvents can be used as alternatives.” [1]

Each extraction method has its pros and cons, with some being more beneficial than others, either for extracting specific compounds or extracting from specific FVW materials. One of the biggest concerns facing FVW extraction is the preservation of the compounds after extraction. Some of these compounds are sensitive to environmental factors like light, heat, oxygen, and pH, which “restricts their utility and bioavailability.”

This is why microencapsulation techniques are being used to protect sensitive compounds. Encapsulating these compounds in a solid matrix protects them from various environmental factors, enhances bioavailability, masks unwanted flavors, and controls release of the compounds in the gut during digestion. There are several encapsulation techniques being used for these purposes, including ultrasound, spray drying, spray chilling, freeze-drying, and using a fluidized bed for additional coating.

Each of these methods then uses a specific wall material, like gum arabic, maltodextrin, or pectin, to encapsulate the compounds. Just like with the extraction methods, each wall material has its advantages and limitations. This is why combinations of extraction and encapsulation methods are being used to extract and preserve specific types of compounds.

Once these compounds have been extracted and encapsulated, they can be added to other food products instead of being wasted. This fortifies those food products with additional valuable food chemicals, valorizing the compounds that would have been wasted in our food supply. The goal of scientists next is to further identify the best combinations of extraction methods and encapsulation techniques to improve and increase the valorization of FVW in the future. [1]

References:

1- Pattnaik, M., et al. Innovative technologies for extraction and microencapsulation of bioactives from plant-based food waste and their applications in functional food development. Foods. 2021;10:279. https://doi.org/10.3390/ foods10020279. Times Cited: 4 (Semantic Scholar) Journal Impact Factor: 4.350