Solventless concentrates are known to be some of the most flavorful extracted products on the cannabis market today, with great care and skill being required to make the very best varieties. If you’re unfamiliar with the term solventless, the category is generally understood to encompass ice water hash (also known as bubble hash), dry sift or kief, and rosin, all of which can be made in numerous ways to please anyone’s palate.

When made properly, each solventless extract offers a true full spectrum experience, rich in terpenes, cannabinoids, flavonoids, and other organic compounds that many other concentrates lack. The primary difference between solventless concentrates and solvent-based ones is that no chemical solvents are used whatsoever, such as carbon dioxide, hydrocarbons such as butane, alcohols like ethanol, and so on. Because there is no process of dissolution as there is with solvent-derived concentrates, the quality of the starting cannabis is absolutely critical to success – there simply is no way to remediate powdery mildew, bugs, or poor-quality material in general with solventless processes.

As a result of the premium level of quality cannabis or hemp that is required, the price points of these concentrates are elevated to match because they often provide exotic terpene and cannabinoid profiles not commonly found in lower priced extracts. Producers take extreme care from start to finish to accentuate rare terpene profiles, and the main point of separation between the elite solventless artisans and the rest is how well they can preserve the highly volatile terpenes that are quickly lost after harvest. In most instances, the best of the best when it comes to solventless is live hash rosin or full melt ice water hash, both of which are made with fresh frozen, never dried cannabis.

Many readers will be familiar with live resin, but live rosin is a term that is now entering the brain space of connoisseurs and those seeking a quality concentrate or infused product. The word “live” as it relates to concentrates indicates that the extract was made with fresh frozen cannabis, as opposed to dried material, because it most closely offers the customer the original flavors and aromas that live cannabis plants do. When high quality cannabis is properly frozen and kept below or near freezing through the entire extraction process, it limits loss of volatile monoterpenes. This is why live rosin, which is made from live ice water hash, is so desirable from a flavor and experience perspective. If you’re looking to make your own solventless concentrates either at home or in a licensed laboratory setting, there are quite a few things to be aware of to maximize your terpene levels in the final product.

Ice Water Hash

Most top shelf solventless concentrates, specifically rosins, are made with live ice water hash. When made “live”, fresh frozen cannabis is soaked and then agitated in an ice water bath, which detaches the trichomes from the buds. To retain as many terpenes as possible, it’s always advisable to keep your cannabis frozen and according to the one study we are aware of on the topic, at or just below -4°F is the sweet spot. [1] When it’s time to wash, make sure that all the water you use is reverse osmosis (RO) filtered, including for your ice, and before you begin agitating, make sure to soak your fresh frozen cannabis in your wash vessel with the ice for at least 15 minutes. Typically, producers will agitate and wash the same batch of material three times (and sometimes more), which results in a water/trichome slurry that is then filtered through various different sized micron screens for grading. If at all possible, perform your wash in a colder room; around 50°F will help keep the entire environment at the right temperature for the best extraction possible.

The next key step is to use freeze dryer at a lower shelf temperature setting to gently dry the bubble hash. This is a key terpene preservation step, and once your freeze dryer cycle is complete, lasting anywhere from 8 to 24+ hours, you’ll want to begin processing it immediately if it’s going to be pressed into rosin. The very best quality ice water hash, known as six-star of full melt, is usually segmented into gram portions, jarred, and put into moisture-proof freezer bags to maintain its sandy-like consistency. High quality ice water hash will grease up quickly at room temperature, so keeping everything cold throughout the entire process is critical.

Dry Sift or Kief

Dry sift and kief are not the same thing, despite the frequent interchangeability of these terms. For our purposes, kief is unrefined trichomes which have been sifted somewhat (think about the kief at the bottom of a grinder) but still contain various bits of plant matter and debris. Dry sift on the other hand is the cleaned, filtered version of kief, which will consist of just dried, isolated trichomes if done correctly. While the process is similar at a surface level to making ice water hash, there is no water or ice involved, and the cannabis is dried and cured prior to being turned into dry sift. This happens through a process of mechanical separation where the trichomes are sheared off the dried buds and then collected. Cultivars that are rich in sesquiterpenes tend to perform well when dried first and then washed or sifted.

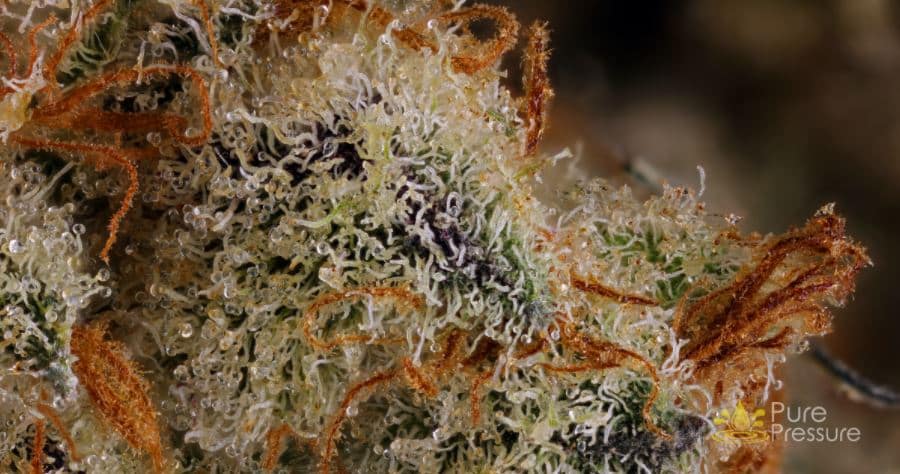

Macro shot of trichomes on Cake Crasher dried and cured cannabis flower

Preserving your terpenes in the dry sift process starts with a well done dry and cure phase of the original cannabis or hemp. In essence, this is where the preservation happens, so each environment has its challenges to do so properly based on relative humidity, temperature, and so on. While keeping things cold is not a factor, you certainly don’t want to be processing your dry sift at high temperatures either. Great dry sift will also grease up when it’s warm, so some testing and experimentation is usually necessary to get your process down perfectly.

Rosin

Last but certainly not least is rosin, which can be made from ice water hash, dry sift, or simply dried buds. With a little post-processing, ice water hash rosin is able to be turned into virtually any concentrate texture imaginable, including vape cartridges, and can also be used to make just about any type of infused product, from edibles to tinctures to topicals. For most processors and enthusiasts, this is one of the most important steps to make sure that their hard-earned terpenes make it all the way through to the final product. Rosin is made by using a rosin press, which utilizes two heated plates, pressure, and filtration media to open up trichomes, expelling the pure resin that they contain. As you may have guessed, heat is a big factor in everything having to do with solventless, and the temperature that you press your rosin at matters enormously. In addition to temperature, time is also a factor, as the longer you press, the more heat you’re exposing your rosin to. In general, for small quantities of any type of pressing, 30 seconds to 2 minutes is a good guideline, whereas for larger quantities of dry sift or ice water hash, 4 minutes or longer is common due to the pressure ramp-up period. Here is a helpful guide of how to press rosin for maximum flavor and terpene content:

Flower rosin: 180°F-220°F

The higher temperature you press at, the higher your yields will be, but it also increases your chances of baking off some of the special volatile terpenes that are still left in dried flower. Find a balance of yield to temperature that suits your needs.

Dry sift rosin: 160°F-220°F

Dry sift rosin has a much larger range, because extremely high-quality dry sift can be pressed at very low temperatures, whereas most dry sift (which is actually kief) must be pressed much hotter to get a satisfactory yield. If you’re pressing kief, plan to press at around 200°F at least.

Ice water hash rosin: 140°F-200°F

Ice water hash rosin can also be pressed at a variety of temperatures, but for many processors, a high-quality bubble hash is often pressed at around the 180°F mark. This is all user preference, but for top terpene retention, experiment with different temperatures. The higher terpene content that exists in the bubble hash to begin with will also dictate the textures that are possible as a result.

When it comes to solventless, preserving terpenes and making a great product all boils down to product quality, environment control during the extraction process, and ensuring that your material is exposed to the least amount of heat possible leading up to pressing into rosin. With these tips and tricks, virtually anyone can make great solventless concentrates with a little experimentation and effort.