Cannabis extraction is the process entailing the extraction of phytocannabinoids and other essential compounds from the plant matter. On an industrial scale the methods most commonly used include:

- Hydrocarbon extraction

- Ethanol extraction

- Supercritical carbon dioxide (CO2)

When choosing the best extraction method for a commercial operation, the following factors should be considered [1]:

- Extraction efficiency

- Extract quality and consistency

- Scalability

- Environmental friendliness

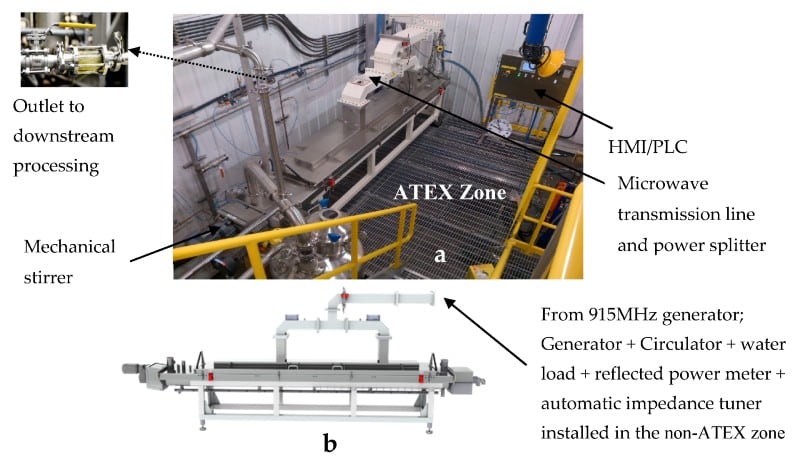

A recent study presented an industrial microwave-assisted extraction (MAE) method that could potentially rival or surpass other methods’ parameters. This is extraction using 915 MHz microwaves together with the use of a continuous flow operation. [1]

Microwave-Assisted Processing

This technology of cannabis extraction using a continuous flow microwave extractor is patented by Radient Technologies, which has been achieving throughputs above 200kg/h of biomass input. [1]

This technique—MAP™, for microwave-assisted processing—involves coupling MAE with continuous flow technology in the extraction of cannabinoids from the biomass. The authors explain that with this method it is easy to regulate extraction time and temperature and hence influence efficiency and quality of the extract.

| The MAP™ extractor in an ATEX (atmosphere explosive) zone. Reprinted from: Radoiu M, Kaur H, Bakowska-Barczak A, Splinter S. Microwave-assisted industrial scale cannabis extraction. Technologies. 2020;8(3):45. License: CC By 4.0 |

The raw cannabis is mixed with an extraction solvent such as ethanol or pentane chosen based on dielectric properties as well as the biomass and concentration of cannabinoids. This mixture is pushed through the continuous flow MAE reactor and then heated to the ideal extraction temperature using 915 MHz microwaves. After this, the biomass and extract are separated. The extract is purged/treated. The biomass is processed to ensure that the tetrahydrocannabinol (THC) level does not exceed the threshold of 0.3% before disposal.

A general concern about this method of extraction has been the high startup cost (capital expenditure, CAPEX). However, it is important to view this in the context of the entire process. This includes analyzing economic advantages vis-à-vis CAPEX. Generally speaking, the CAPEX is between $1,000 and $5,000 (USD) per kilowatt of microwave power installed. This also varies depending on the power range and the equipment used. That said, this system easily achieves >90% operation efficiency.

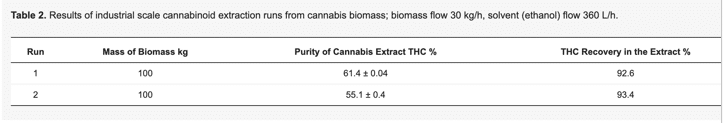

The study noted “commercial sensitivity of the subject,” and therefore data was “limited to two examples without the full disclosure of the operational conditions of the extraction.” This data is reprinted from the open-access study in the table below.

| Reprinted from: Radoiu M, Kaur H, Bakowska-Barczak A, Splinter S. Microwave-assisted industrial scale cannabis extraction. Technologies. 2020;8(3):45. License: CC By 4.0 |

The authors compared (in general terms) this method with the other commercial extraction methods and the following advantages were discussed for MAP™:

- Efficiency: It allows for higher amounts of biomass to be processed in a shorter time as compared to existing extraction methods. It eliminates some steps such as biomass decarboxylation and winterization.

- It provides high yields with about 95% extraction efficiency of the active cannabinoids.

- Improved product quality and consistency: The process can flow continuously without stopping and restarting the material flows.

- The process is easy to scale up. [1]

The cannabis industry is still in its infancy and methods of extraction continue to evolve. It appears that industrial scale microwave assisted extraction has unique opportunities that can be exploited.

Image Source

Reference

- Radoiu M, Kaur H, Bakowska-Barczak A, Splinter S. Microwave-assisted industrial scale cannabis extraction. 2020;8(3):45. (Impact Factor: n/a; Cited: n/a)