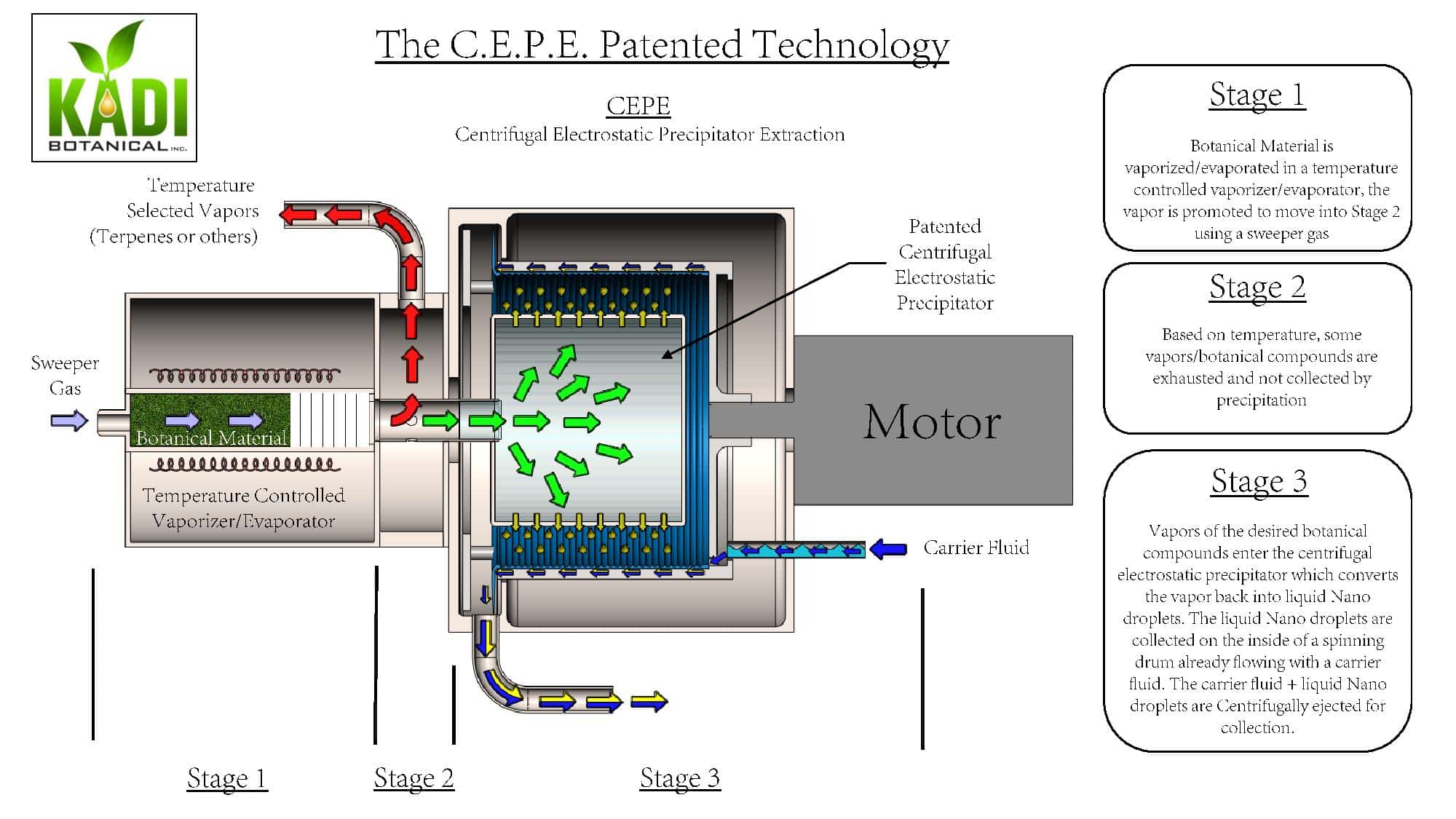

KADI Botanical Inc. recently revealed their Phase II Centrifugal Electrostatic Precipitator Extraction (CEPE) technology, an emerging technique that extracts botanical compounds from biomass by evaporating compounds directly from dry botanical matter — all without the use of solvents. While this extraction technology is still in the works and will undergo extensive analytical testing in the coming months, we were lucky enough to speak to Kevin Dooley, CEO of KADI Botanical Inc and one of the inventors of the CEPE technology.

“Vaporized compounds – such as tetrahydrocannabinol [THC], cannabidiol [CBD], and others – are carried by a temperature-controlled inert gas (oxygen-free), such as nitrogen,” Dooley explains, “from the botanical material in the vaporizer section to the electrostatic precipitator section, where the vapors are converted into a nano-droplet liquid form and collected in the centrifugal collection section.”

These nano-droplets are then directly combined with your desired carrier fluid, whether vegetable glycerin (VG), ethanol, or medium-chain triglycerides (MCT) oil, just to name a few. It should be noted, however, that the nano-droplets can still collect as a liquid without the use of a carrier fluid. The botanical matter and carrier fluid never come into direct contact with one another and, therefore, all potential contaminants (heavy metals, waxes, etc.) remain in the botanical material waste.

“Generally speaking, each compound tends to evaporate from the botanical material over a specific temperature range [normal operating temperature range is currently between 40℃ and 200℃],” Dooley continues. “As such, it is possible to perform somewhat selective extractions of specific compounds if desired. This selectivity is improved by the action of the fractionating reflux beads at the output of the vaporizer section. Unwanted compounds that evaporate during the process at specific temperatures can bypass the precipitator and be disposed of or treated alternatively.”

Due to the temperature range, Dooley and his team have been able to extract low-temperature cannabis terpenes separately through a cold trap. They’ve also been able to decarboxylate the biomass throughout the warm-up to the extraction range of temperatures. Thanks to the electrostatic precipitator, anyone who operates CEPE can keep a close eye on various aspects of the extraction cycle – from the progress of decarboxylation and vaporization processes to the overall completion status.

“By monitoring certain electrical parameters related to the operation of the Electrostatic Precipitator, we can monitor the density of the flow through the precipitator,” Dooley details. “By comparing this density to the density of clean nitrogen, we can tell if the nitrogen has any other compounds mixed with it (and how much). When there are none, then there is no more vapor or other gasses (such as carbon dioxide during decarboxylation) coming from the vaporizer. The temperature the nitrogen gas is at is an indication of which compound we are monitoring.”

What makes this technology ground-breaking is that you can gain cannabis extract entirely through one machine – only using dried cannabis flower and a carrier fluid. Such efficient technology could completely change the cannabis industry – however, it’s too early to tell for certain at this point.

“The CEPE technology is still in its relatively early stages,” Dooley notes. “However, all in all, the CEPE process (machine) allows the direct production of saleable products using only the botanical raw material and the desired carrier fluid plus electricity. The VG product we have shown is very repeatable and can be used as a tincture directly out of the machine. It can be mixed with water or water-based drinks to make beverages. It can also be mixed with various edibles, or it can be used directly as an ointment.”

Since this technology remains in its early stages, it’s difficult to tell how much more efficient it might be when operated on an industrial scale. There are still several tests Dooley and his team would like to run, such as high potency THC and isolate extractions, as most of their trials have been on broad-spectrum extracts.

Still, while Phase II CEPE lab unit currently processes 100 grams per batch, KADI’s goal is to make the industrial scaled machine operational to extract upwards of 200 kilograms of biomass per day. The industrial machine is being designed and constructed as a portable system to allow transportation to production facilities for technology demonstration purposes.

“We have demonstrated for our own purposes that we can selectively extract compounds based on the temperature range of the extraction and expect this to be useful to perhaps modulate THC vs CBD content when required, such as reducing THC content in hemp CBD extraction,” Dooley explains.

Not to mention, there’s much optimism that Phase II CEPE will be able to extract botanicals from other plant matter. However, KADI’s current focus is on cannabis.

It’s also important to mention that Dooley and his team have noted the rising popularity of homebrew extractions. While Phase II CEPE is currently keeping its focus on industrial production – more particularly, with facilities that operate in cannabis-infused beverages – this technology does hold the potential for homebrew functioning.

Dooley’s journey with this new technology began with Phase I CEPE, a machine of similar operations that was used to prove the concept and is still in full use today. Phase I CEPE was designed for smaller quantities of botanical matter, up to 20 grams per batch.

“Twenty grams may not sound like a lot of botanical material,” Dooley understands. “But we have demonstrated production of 2 gallons per hour of a water-based cannabinoid beverage at 1,800 mg of THC per gallon. The maximum allowable THC content for legal beverages in Canada is presently set at 10 mg per package. So, this production could conceivably make as many as 360 legal-sized cannabis drinks per hour [the length of one batch run].”

The Phase II CEPE machine incorporates all of the technology improvements implemented during the development program on Phase I, the primary change was to shift from the horizontal orientation of the machine to vertical. By incorporating the rotational and flow axis in a vertical direction – rather than a horizontal direction – the centrifugal ejection is improved and allows for upwards of five times the capacity of botanical material to be loaded into the vaporizer.

“The unit is still considered to be quite a small unit,” Dooley explains. “But is intended to prove out a couple of other technical features related to the improved centrifugal ejection of all of the product types.”

Again, Dooley and his team remain in the early stages of this new technology. However, there’s no denying it holds promise for more efficient and higher-quality cannabis extractions.

“We are very excited about the CEPE process and realize that we still have quite a bit of work ahead of us,” Dooley proclaims. “KADI Botanical Inc. has received excellent support from our shareholders and we are very confident that we have something very unique here. We target to begin testing the industrial-scale machine around the end of 2020.”

This technology is currently issued and pending for patent worldwide.