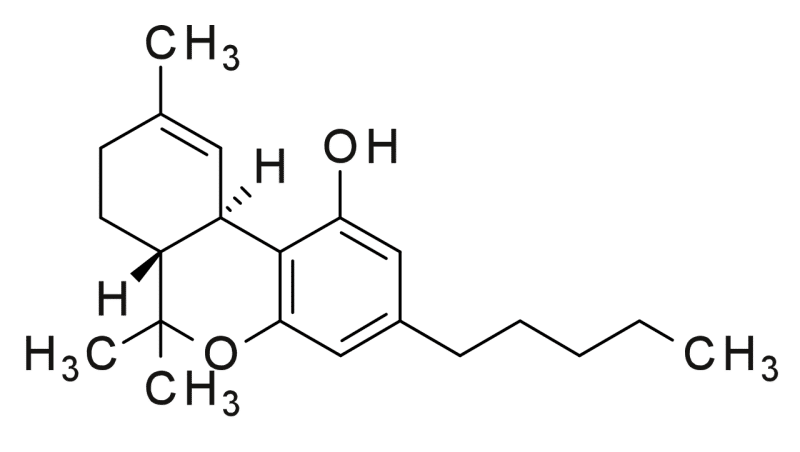

Delta-9–tetrahydrocannabinol (THC) is the center of attention as far as medicinal cannabis goes, though some would argue for cannabidiol (CBD). Foundational to THC research and the use of THC concentrates is the extraction, isolation, and purification of THC. Two methods are covered here: supercritical fluid extraction (SFE) and solid phase extraction (SPE).

What is SFE?

Supercritical fluid extraction (SFE) is the process of extracting a compound from another using fluids in supercritical conditions. [1] In cannabis, this means extracting THC from the plant material (Cannabis sativa L). Carbon dioxide (CO2) at supercritical conditions is commonly used to extract cannabis compounds on a commercial scale. The CO2 can be modified to enhance polar solubility with co-solvents such as ethanol or methanol. [1]

CO2 is a gas at standard temperature and pressure. When compressed at supercritical conditions—1070 psi, 8.38 MPa, or 73.8 bar (critical pressure) or higher and a temperature exceeding 31°C—it is converted to a supercritical state.

Supercritical liquids have a gaseous and liquid nature and pass through porous solids such as plant materials. [1] In cannabis, supercritical CO2 extraction targets maximum phytochemical output while maintaining low levels of contaminants such as chlorophyll in the final product.

What is SPE?

Solid-phase extraction involves introducing a liquid sample to an extraction cartridge containing a solid phase that is capable of extracting analytes and maintaining them on the solid phase. The analyte — THC in this case — must have a greater affinity for the solid phase than the liquid matrix. The analyte is then eluted from the solid phase.

Study Investigating SFE & SPE

In a 2019 study, THC was extracted from cannabis using supercritical CO2 and was isolated/purified using solid phase extraction. [2]

In the SFE process, different pressures (15–33 MPa) and temperatures (40–80 °C) were evaluated. Ethanol (0-5%) was also used as a co-solvent.

The effect of extraction parameters on THC yield was evaluated. Overall, the highest extraction yield was obtained at 33 MPa, 80°C, and 5% ethanol.

At a constant temperature of 60°C and ethanol concentration of 2%, the highest THC content was obtained. At these conditions, pressure variations generated:

- 85% THC at 33 MPa

- 18% THC at 15 MPa

The THC-rich extract was then submitted for purification-isolation through single-step SPE. The authors used modified silica gel in the column, trifluoroacetic acid in water as a solvent, and trifluoroacetic acid in acetonitrile as an eluting agent. This yielded a fraction with a 90.1% THC concentration as analyzed by gas chromatography-flame ionization detection (GC-FID).

Study Findings

The authors conclude that the combination of SFE & SPE sequentially produces a THC extract with high purity levels. They report that “from 100 g of Cannabis sativa L [sic] plant material subjected to a sequential SFE-SPE process, it is possible to obtain 13.97 g of THC enriched extract and 3.55 g of high purity THC.” They also note it was “obtained at low cost and with fully affordable resources.” [2]

It appears that combining SFE with SPE is an efficient process for high-output and high-purity THC extractions from Cannabis sativa L.

Image Source: https://commons.wikimedia.org/wiki/File:THC_structure.svg

References

- Sapkale N, et al. “Supercritical Fluid Extraction: A Review.” Int J Chem Sci, vol.8, no.2, 2010, pp.729-743. [journal impact factor = 0.287; times cited = N/A]

- Ada C, et al. “Extraction, Isolation and Purification of Tetrahydrocannabinol from the Cannabis sativa Plant using Supercritical Fluid Extraction and Solid Phase Extraction.” The Journal of Supercritical Fluids, vol.146, 2019, pp.208-216. [journal impact factor = 3.481; times cited = 9 (ScienceDirect)]