The Past and the Future

Concentrates are obtained when the individual chemical constituents inside a material matrix (such as plant matter) are selectively extracted. This mainly, but not always (e.g. rosin presses), happens due to preferential solubility of chemical constituents in an extraction solvent. In the cannabis industry, concentrates are sold as diverse products, many of which require additional post-processing steps beyond outright extraction. The goal of post-processing is to achieve some degree of purification, usually through lipid removal (winterization) and/or distillation.

Distillation of cannabis extracts requires delicacy for two main reasons. First, there is a massive gap in boiling points between the average terpene and any cannabinoid (roughly 100°C). Heating the reaction mixture to temperatures required for cannabinoid distillation for any length of time thus results in significant loss of terpenes from the collected end-product, not in this case due to degradation, but because terpenes began boiling and eluting long before cannabinoid collection began. Second, for molecules like cannabinoids, and especially terpenes, heat is death; they degrade. In the best-case scenario, degradation leads to chemical inactivity, which is obviously undesirable. In the worst, it creates an unpleasant “burnt” taste and makes the product unsellable.

These challenges are not unique to cannabis extract manufacturing, and resolving them has been an ongoing effort in the field of chemistry for many years. Newer methods to improve efficiency focus on A) lowering the temperature requirement for efficient distillation, and/or B) decreasing the time molecules must be exposed to heat.

Historically, achieving these goals has been challenging. The boiling point, or temperature at which a compound enters the gas phase, is a function of the pressure in the system (among other factors), and without the technology necessary to create a vacuum, the pressure is mostly limited to atmospheric pressure (i.e. whatever the pressure is in the room you’re in when the reaction takes place). However, the boiling point also depends on the partial pressure of the particular compound of interest in the system, and this is where steam distillation comes into play. Steam distillation uses gaseous water (steam) to facilitate the vaporization of aromatic compounds at lower temperatures than they could otherwise be distilled in.

Consider this scientific rationale. Compounds boil when vapor pressure equals system pressure, and while the vapor pressure is the sum of all partial pressures of gases in the system, many distillations can reasonably simplify the situation by assuming that the vapor pressure, P, is solely due to the partial pressure of the compound of interest, e.g. P1.

Clever scientists, however, showed that by combining the vapors of two immiscible compounds in the same reaction vessel, the vapor pressure in the system becomes a sum of the two partial pressures P1 and P2. This causes the boiling points of both compounds to decrease, because the partial pressures they need to achieve for their sum to equal atmospheric pressure are lower in the two-compound system than they are individually.

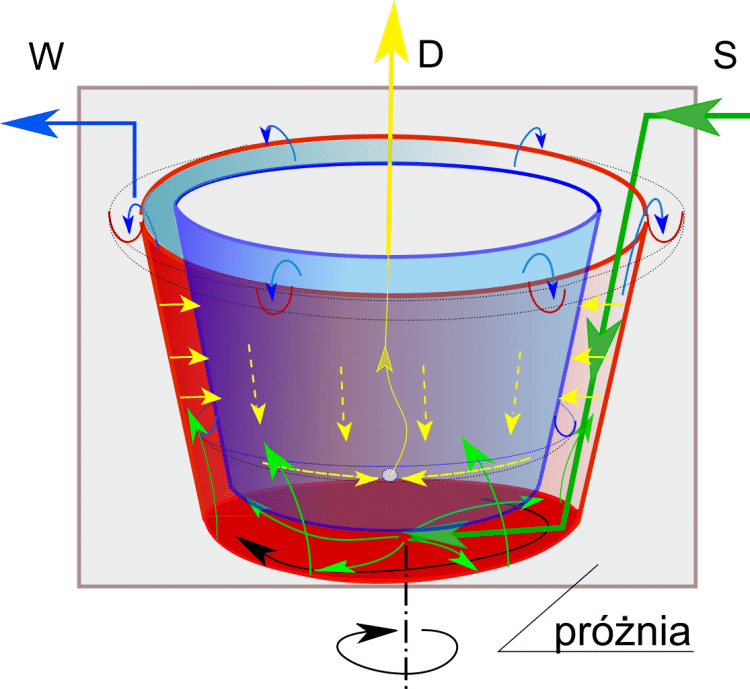

Short-path distillation is a topic that has been covered ad nauseum, but molecular distillation is an interesting subcategory of this technique. Whereas steam distillation reduces the temperature requirement for distillation (challenge A), molecular distillation greatly reduces the amount of time molecules must spend at high temperatures (challenge B). Molecular distillation uses a very high vacuum system which effectively reduces the pressure in the system to zero and allows compounds to essentially vaporize instantaneously. [1] The distillate proceeds in a continuous-feed fashion, and the rate of distillation depends on flow velocity and surface area of the heating and cooling blocks. Read here to learn how molecular distillation was used to invent nylon!

While steam distillation is a beautiful illustration of scientific ingenuity, it became outdated in all but a few applications with the invention of the vacuum distillation apparatus. Molecular distillation, on the other hand, represents the future direction of large-scale concentrate post-processing efforts.

References:

- Vogel, Arthur I. Vogel’s Textbook of Practical Organic Chemistry, 5th Edition. Longman Scientific & Technical, Harlow 1989. Chapter 2: Experimental Techniques, Section 2.28: High Vacuum Distillation – Molecular Distillation, Pages 186-190. Available at [org]