Factors that might account for the differences in viscosity seen in otherwise equal batches

In the extraction and cultivation industry, the saying goes, “All Cannabinoids are not Distributed Equally.” Meaning, that there are real differences in the way cannabinoids are localized in a given plant.

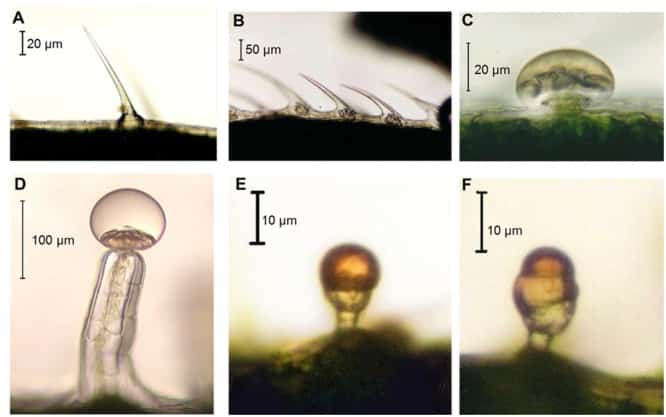

First, there are the obvious distinctions. Seeds, stems, and stalks of cannabis contain much lower concentrations of both cannabinoids and terpenes compared to flowers and leaves [1]. This is the main reason hemp seeds have been legally marketable in food stores long before the legalization wave began sweeping across America.

Then, there are the more scientific breakdowns. For example, THC expression has been found to be dependent upon light exposure. [1] It was therefore found to follow a top-down hierarchy, with

Another reason besides cannabinoid and terpene content could be the different levels of plant waxes that exist on different parts of the plant. All plant surfaces are coated with a waxy layer that keeps the interior airtight, preventing gas and moisture exchange with the external environment, except through specific apertures on the leaves and roots. Because leaves are thin and light, they will contain a higher relative amount of these waxes compared to, say, the stem or stalk. And since these waxes are dissolvable in the hydrophobic solvent used in cannabis extractions, batches can show a difference in viscosity depending on their ratio of leaves to flower to stems and stalks.

Finally, something as simple as differences in dissolved solvent will affect the viscosity of different batches. If two batches of starting material, of equal weight and soluble oil content, spent different amounts of time in the solvent reclaim phase of the extraction process due to user or systemic error, then naturally a difference will be seen in their viscosities. Never rule out error on your part in accounting for these differences.

To minimize these inter-batch viscosity differences, it is recommended to mix together all the trimmings obtained from a given plant before dividing it into individual batches. This will create batches with reasonably equal ratios of flower to leave to stem. And, always make sure you are meticulously following standard operating procedures.

References

- Andre, Christelle M., et al. “Cannabis sativa: The Plant of the Thousand and One Molecules”. Front Plant Sci. 2016; 7: 19. [Times cited = 136, Journal impact factor = 4.298]

- Pacifico, D., et al.“Time course of cannabinoid accumulation and chemotype development during the growth of Cannabis sativa L”. Euphytica. 2008; 160: 231–240. [Times cited = 36, Journal impact factor = 1.548]

Image Citation: Andre et al, 2016