Performing Extractions of Natural Products that are Out of the This World

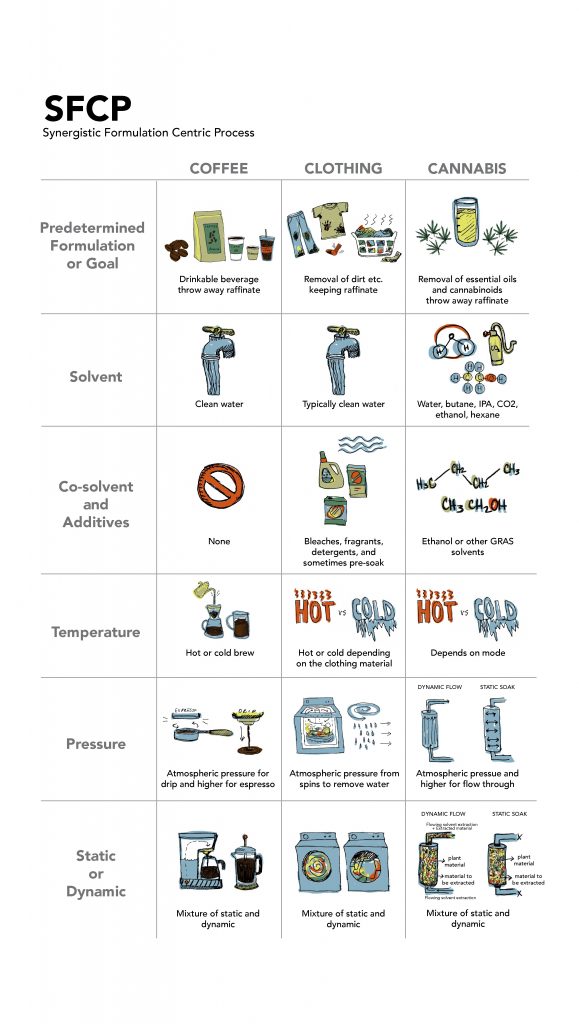

I want to use the extraction of a common natural product (roasted coffee beans), to describe the extraction of a biologically active ingredient (caffeine) and the other essential oils, flavors and fragrances by water and supercritical carbon dioxide (CO2). After that I would like to compare to extraction micro distillation versus SFE by CO2 of essential oils from cannabis plants.

EXTRACTING OUT OF THE THIS WORLD?

Yes, really that is what we are doing in the modern world today. Technology has become so common to us that we forget that we are walking through a virtual science lab. Interestingly enough, we have created compact Un-Earthly worlds inside our daily life on Earth.

If you assume that where you live, and the conditions you live in, are natural atmospheric reality on the planet Earth, then anything outside of that reality is not a natural reality.

Scientists, test conditions that are outside of the limitations of Earth’s atmosphere. Any time an experiment is designed and conducted at different temperatures, different pressures, etc.from the Earth’s atmosphere, they are changing our natural conditions.

We have become so used to our “air-conditioned” buildings that we have forgotten the weare living “out of this world.”Even in our air-conditioned homes, we have some of the scientific apparatus thatwe use every day, were capitalized on by an “entrepreneur”. Now we have small units that are colder or warmer than our local natural reality. We call these refrigerators and ovens.Of course, these were not fast enough for our lives, so then came microwaves and convection ovens.

What has this got to do with the extraction of cannabis and how that fits into this modern world you live in today?

I like to start my day off with the extraction of coffee. The decaffeination of roasted coffee, as well as the flavors and fragrances are something I do for the physiological effect, as well as for the taste and aromas. If I did not, then I would take a pill with 100 mg/tablet of caffeine.

There are at least three extraction modes using water (H2O) as my extraction fluid that are possible; flow through, steeping, and percolation.These we will see are similar to extraction of cannabis with dynamic, static and recirculation of supercritical carbon dioxide.

The first is a simple flow through extraction with hot water with, Chemex, for example, which got its start from a modified Erlenmeyer flask.

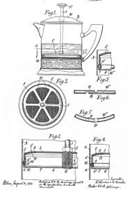

The second is one with steeping of the coffee and then filtering. The coffee press, patented by Milanese designer Attilio Calimani in 1929, is an example of this mode.

My coffee beans came in an air tight pouch. Many people keep this in the freezer to keep in the flavors and fragrances that would be lost over time if they were stored on a shelf in the Earth’s conditions.

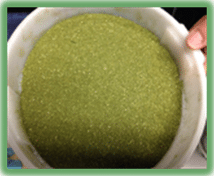

My caffeine loaded natural product needs to be ground or it will not be able to provide me with the yield of caffeine I want (need). I grind it to provide more surface area. The finer the particles, the more material will come from the extraction.

I opened the package and took my imprecise measuring device and placed 4 heaping scoops into my grinder. I grind and then transfer the material onto a filter paper that was on top of coffee maker.

Meanwhile I have been boiling the water on my scientific instrument (a kettle filled with water heated on the stove) until it is at the temperature I want – in my case boiling. I added enough water to fill the filter paper. The hot water drains through the ground beans and passed the filter paper and into the lower glass. When is has drained, I repeat the process until I have put about 8 cups of boiling water (H2O) through the system. In my process I have a 4 scoops coffee ground to 8 cups water (2 cups/1 scoop) ratio for the extraction formulation I prefer of this type of coffee.For a weaker coffee I would increase the number of cups per scoop, for more concentrated I would use less. This ratio has a large impact on the material that is extracted. If I used less water, I would be leaving some of the caffeine left in the grounds. I have too much water, then I would have all the caffeine, however I might begin to extract other material out of the grounds.

This is not true of all people. I have a set temperature of water, a set flowrate of water based on how fast I pour it, and a collection vessel. Out came dark colored water. I could smell “coffee” and knew it would taste like it had the day before and give me the experience I had had the day before. [So, I have quality control lab of crude variety.]

Other people use a “French Press”, in which they put coffee grounds in a container and then add hot water to it and let it set for a specific amount of time and then filter and pour out from it.

- I have chosen to prepare the sample and place in a container of choice. It is a variety of choice with different compounds that will have a different profile of active ingredients, non-active ingredients, flavors, fragrances, etc.

- I have chosen to do flow through or steep the product. So,I have chosen, dynamic or static extraction.

- I have chosen the conditions that provide me the “good enough” extraction.

I did not choose cold water, or warm water, or steam. I chose boiling or hot water. Why did I not choose cold water? It is still water. Or warm water? It too is water. Or even steam? It too is water. All of those choices would not have EXTRACTED the compounds that I was wanting from this botanical in the time I had at this time.

Which brings us to “cold brew coffee”. What is different about the cold brew versus the “hot brew”? One is that is takes longer and second is that it does not extract as much of the acidic compounds that hot water does. This is the same with extraction of cannabis. The conditions will determine the components that are extracted and which compounds are extracted.

Though it is possible for me to use supercritical fluid with CO2 for the coffee extractions in my kitchen, my recent cost of analysis had confirmed (again) that this is not in my financial or time budget. For a small extractor for SFE, would be far too expensive to justify. However, I will cover how you might perform this incase it does match your criteria.

If you wanted to ONLY extract the caffeine and leave behind everything else? How would you have done that? In the early days they used organic solvents, such as benzene and methylene chloride. These would be removed later in the process, however, there still could be some residuals remaining if not done correctly. In 1967, at the Max Planck Institute for Coal Research, Kurt Zosel discovered coffee

decaffeination using Supercritical CO2 as his solvent. Note from this work it is possible for people to still enjoy the flavors and fragrances and experience of coffee with less caffeine.

Based on more study, the solubility of pure caffeine in CO2 is about 0.2 wt-% at 300 atm, 60-degree C. This is critical to know, just as it was critical to know the type of solvent (water) and temperature (boiling, not Earth’s room temperature in my case) for the extraction for my morning coffee. If you were to assume that the typical amount of caffeine in a plant is about one percent by weight (1 wt-%), then at those conditions how much CO2 would it take to extract all of the caffeine in one pound of coffee? I am assuming the perfect conditions that nothing else is going to affect the extraction – like all the other things that really do affect it like moisture, other compounds in mixture, size of containers, etc. etc. etc. – for this quick estimation.

For one pound at 0.2 wt-% solubility above, it would take five pounds of CO2 to extract the caffeine from one pound of coffee. That solves the thermodynamics (sort of) but not the mass transfer (flow rate). We will get to that next time. But, coffee, like all-natural products, is a much more complicated extraction. In a way the complexity is assuring to me, as it provides job security for chemists, chemical engineers and financial analysts. Dr. Richard Smith, Jr. et. al. has a written a great summary on it, and is well worth the time for those interested.

| Operation | Coffee | Cannabis |

|---|---|---|

| Grinding |  |

|

| Placing in extraction vessel |  |

|

| Extracting enriched compound |  |

|

What has my morning coffee got to do with research lab in Turin, Italy and terpenes from industrial hemp? In this experiment, I have used the same general procedure as I would with Supercritical Fluid CO2 extraction. There are many more nuisances with the decaffeination, that had to be solved to maximize it, as there is with the maximizing the workflow with industrial hemp.

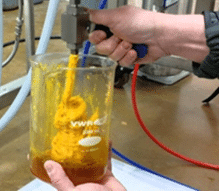

A recent paper by Dr. Carla Da Porto at University of Udine and her team compared and contrasted the micro-distillation and SFE with CO2 for the extraction of the terpenes in industrial hemp. And with the use of multiple collection vessels at different pressures and temperatures allows the preferential collection of the terpenes in one vessel rather than another. BUT they must be captured and handled with care. In their case:

“The extractions were performed at pressure of 10 and 14 MPa and temperature of 40 ◦C. On-line fractionation of the extracts was accomplished maintaining Cyclone Vessel S1 at 7 MPa and 25 ◦C and Cyclone Vessel S2 at 5 MPa and 15 ◦C in both experimental assays. CO2 flow rate was set to 3 kg/h in both experiments (CO2/inflorescences = 80 kg/kg). Extractions were carried out by duplicate. The samples recovered in S1 were solid and pasty. S2 fractions were collected into a cold trap cooled with liquid nitrogen and had oily appearance. The fractions obtained in S1 and S2 were recuperated and placed in vials. They were weighted and kept under N2 at −20 ◦C in the dark until analysis.”.

With CO2 in supercritical state, if hold the temperature constant and increase the pressure, it becomes more polar and therefore more soluble for compounds. Think of it like raising the temperature of water for my caffeine. It is more complex, but allow me to venture into glittering generalities. Note, however that not all compounds have the same solubility at the same temperature, nor do all the terpene family have the same solubility.

While the SFE with CO2 gave better results based on different conditions, it was also more energy efficient. This is something moving forward will be important consideration as plants begin scaling in size.

“It is to be noted that extraction by supercritical CO2 is particularly advantageous in terms of energy consumption because of the small volume of solvent introduced, the separation of the extract by decompression, plus the fact that it is possible to recuperate the calories produced by the cold group (passage from gas form to liquid form) to feed the heating system (passage from liquid form to supercritical state).”

General conclusions for today?

- You are doing natural product extractions every day. It is not new to you or the world of science. However, the basic principles and practices can’t be skipped over in daily world or industrial hemp. If you do not define where you are going, any road will get you there, eventually. The eventually rarely be ahead of the team that knows where they are going. Iterative innovations, and pivoting due to unanticipated challenges are very different from haphazard experiments and wandering aimlessly through woods hoping to find gold.

- Standing on the shoulders of giants. The possibility that others have been challenged by similar circumstances before is high. Applied science. It might not be exactly the same, but there are many libraries across the country. The people in them have advanced degrees in library science. It is their passion to help others open doors to through research. They don’t know the answers, but they know how to help you find places for you to explore for them. And I gave you some references as conversations starters, to start you off on your journey to ask the help desk.

Hoping you extract the best from your day.