What’s the Difference?

Following up on last week’s article, we were interested in probing which specific type of Short Path Distillation, or SPD for short, is the ‘green standard’ of the cannabis extract industry.

As discussed before, SPD is used mainly when the products being distilled are thermally unstable. [1] That means they cannot bear to stay at high temperatures for long before breaking down and losing their effect. Hickman and Co. figured that if you reduce the distance molecules had to travel (the path) in the distillation apparatus, you would reduce the amount of time the molecules spent under heat, and therefore reduce thermal degradation. [2]

This technology, well in-place before the 1940s, has given rise to several different flavors of SPD. Among them is Wiped Film Distillation, and it is the chief star of today’s show.

The science behind film distillations, in general, is sort of intuitive, if we begin to understand the molecular picture behind it. When in a liquid state, molecules exist as a sort of conglomerated, loosely-bound glob, each transiently attached to the molecule next to it in a network of continuously breaking and reforming chemical bonds. Distillation, or separation of the molecules, is achieved when certain molecules leave the bulk volume due to differences in their physical properties—most commonly, evaporation via differences in boiling points.

As we know from personal experience, the rate of evaporation of a liquid depends on its surface area. Think pan vs. pot: which would you use to make a reduction, and which a soup?

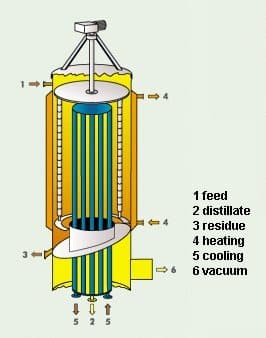

Therefore, a thin film of liquid should allow for increased molecular evaporation. In a wiped-film, short path distiller, this film is established by a feed of liquid which emerges from continuously-rotating sets of metal wipers. These wipes circumvent the inner aspect of the distiller wall at a predetermined speed, chosen depending on the composition of the liquid being distilled.

The wiping speed together with the liquid feed output (in units of volume), distance or path traveled, and total residence time determines the efficiency of this process. [3]

References

- Najder, Leonard E., “Thin film Evaporation”. Indus. and Eng. Chem. 1964:56(2);26-30 [Times cited = 12, Journal impact factor = 2.843].

- Hickman, K.C.D.,“High-vacuum Short-path Distillation-A Review”. Chemical Reviews. 1944:34(1);51-106[Times cited = 84, Journal impact factor = 52.613].

- Nguyen, Anh-Dung, and Le Goffic, François.“Limits of wiped film short-path distiller”.Chem. Eng. Sci. 1997:52(16);2661-2666 [Timescited = 18, Journal impact factor = 2.895].