Pulsed Electric Field (PEF) technology involves applying short bursts of high voltage electric fields to biological materials. Essentially, food products or biomass are placed between two electrodes, and an intense electric field (typically 1–50 kV/cm) is applied for microseconds to milliseconds.

This process causes a phenomenon known as electroporation, wherein the cell membranes become temporarily or permanently permeable. This effect facilitates:

- Rapid mass transfer of intracellular compounds, such as juices, oils, or bioactives.

- Disruption of microbial cells, leading to non-thermal pasteurization.

- Enhanced extraction yields and process efficiencies.

Importantly, PEF achieves these effects without significant heating, preserving heat-sensitive nutrients and flavors.

What is Cold Plasma Treatment?

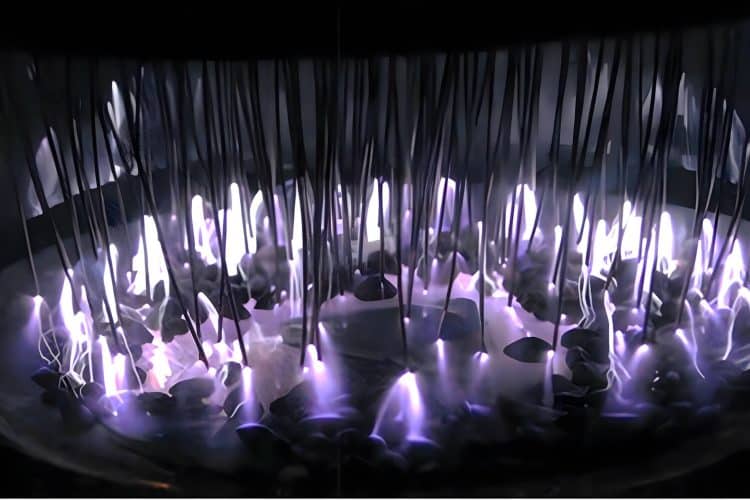

Cold Plasma is an ionized gas that contains reactive species, such as ions, electrons, and radicals, generated at or near room temperature. Cold Plasma is produced by applying energy (e.g., radiofrequency, microwave, or dielectric barrier discharge) to gases like air or nitrogen.

Cold Plasma interacts with biological surfaces, providing benefits such as:

- Microbial inactivation by damaging cell walls and DNA.

- Surface modification, enhancing wettability or extraction properties.

- Degradation of pesticide residues or contaminants.

These unique properties make Cold Plasma a highly attractive non-thermal pretreatment method.

Historical Evolution of PEF and Cold Plasma Applications

The roots of these technologies trace back several decades, but recent advances have propelled them into mainstream industrial use.

Milestones in PEF Technology Development

PEF research began in the 1960s, primarily focusing on microbial inactivation. Early prototypes were limited to lab scale due to power constraints.

Significant milestones include:

- 1980s–1990s – Commercial interest grew for juice pasteurization.

- 2000s – Equipment capable of treating thousands of liters per hour was developed.

- 2010s – Widespread adoption in potato and tomato processing.

Today, PEF is considered a mature technology for multiple food and bioprocessing applications.

Evolution of Cold Plasma in Industrial Use

Although Cold Plasma has been used in semiconductor cleaning for decades, its food applications emerged only recently:

- Early 2000s – Proof of concept studies for microbial inactivation.

- 2010–2015 – Development of atmospheric plasma systems suitable for foods.

2020s – Integration into packaging and surface decontamination lines.

Mechanisms Behind Efficiency Enhancement

PEF & Cold Plasma pretreatments break efficiency ceilings because they fundamentally change mass transfer and microbial dynamics without relying on high heat.

Cell Membrane Permeabilization by PEF

PEF’s electroporation increases the permeability of cell membranes, creating microscopic pores. This effect:

- Reduces resistance to solvent flow.

- Enhances the release of intracellular contents.

- Enables faster extraction of juices and oils.

For example, in tomato processing, PEF treatment can increase juice yield by 20–30%, while preserving color and nutrients.

Surface Modification and Decontamination by Cold Plasma

Cold Plasma generates reactive oxygen and nitrogen species that:

- Inactivate bacteria, yeasts, and molds on surfaces.

- Modify the microstructure of plant surfaces, improving extractability.

- Break down residual pesticides or allergens.

Unlike chemical treatments, Cold Plasma leaves no harmful residues and requires minimal water or solvents.

Applications in Food Processing

These technologies have reshaped how the food industry extracts, preserves, and enhances products.

Enhancing Juice Extraction Yields

PEF has demonstrated remarkable success in juice processing:

- Apple juice: up to 10% higher yield and improved clarity.

- Carrot juice: enhanced carotenoid extraction.

- Sugar beet: increased sugar recovery with lower energy input.

Microbial Inactivation and Food Safety

Cold Plasma is highly effective for decontaminating:

- Fresh produce surfaces.

- Nuts and grains.

Food packaging materials.

It offers an alternative to thermal pasteurization or chemical disinfectants, improving shelf life while retaining sensory qualities.

Bioprocessing and Bioactive Compound Recovery

Beyond food, PEF & Cold Plasma are advancing bio-based industries.

Extraction of Bioactives and Functional Ingredients

Examples include:

- Polyphenol recovery from grape skins.

- Protein extraction from algae.

- Oil extraction from seeds and nuts.

PEF can shorten extraction times by up to 50% and increase yields by 15–30%.

Waste Valorization and Sustainability Impacts

Cold Plasma can degrade recalcitrant contaminants, enabling the use of byproducts in animal feed or biofertilizers.

PEF improves processing efficiency, reducing energy and water consumption. Together, these benefits support circular economy models.

Industrial Scale-Up and Economic Considerations

While promising, implementation requires careful assessment of feasibility and costs.

Equipment Costs and Operational Efficiencies

- PEF systems: initial investments can exceed $500,000, but payback periods are favorable due to yield gains.

- Cold Plasma: equipment is modular and scalable, with energy consumption comparable to thermal treatments.

Regulatory and Safety Considerations

Both technologies are recognized as safe when operated within defined parameters. However, compliance with food safety standards and validation protocols is essential.

Comparative Analysis: PEF vs Cold Plasma

| Aspect | PEF | Cold Plasma |

| Mechanism | Electroporation | Reactive species interaction |

| Target | Bulk processing | Surface treatment |

| Yield Enhancement | High | Moderate |

| Microbial Inactivation | Moderate | High |

| Heat Sensitivity | Minimal | Minimal |

| Cost | Higher | Moderate |

Each technology has unique strengths, and they can be combined for synergistic effects.

Future Trends and Research Directions

Emerging trends include:

- Hybrid systems combining PEF, Cold Plasma, and ultrasound.

- AI-based process optimization.

- Applications in plant-based protein and alternative meat processing.

FAQs on PEF & Cold Plasma Pretreatments

1. Are PEF and Cold Plasma treatments safe for consumers?

Yes. Both methods are non-thermal and leave no harmful residues when properly applied.

2. Do these technologies affect taste or nutritional quality?

Generally, they help preserve flavors and nutrients compared to thermal treatments.

3. Can PEF and Cold Plasma be used together?

Yes. They can be sequentially applied to enhance yield and microbial safety.

4. What industries are adopting these technologies fastest?

Juice processing, dairy, and plant-based ingredients sectors.

5. Is Cold Plasma suitable for liquid products?

Primarily used for surfaces, though some research explores liquid applications.

6. What’s the payback time for investing in PEF equipment?

Typically 2–4 years, depending on scale and throughput improvements.

Conclusion

PEF & Cold Plasma Pretreatments Break Efficiency Ceilings by offering unparalleled improvements in extraction, decontamination, and sustainability. As industries move towards greener, cleaner technologies, these approaches will play a pivotal role in shaping the future of food and bioprocessing.