The relentless drive toward cleaner, more efficient extraction methods has propelled supercritical fluid extraction (SFE) and pressurized liquid extraction (PLE) into the spotlight. While each technique independently offers substantial benefits over conventional solvent extraction, their sequential combination represents a paradigm shift. Multistage SFE–PLE pipelines harness the complementary strengths of both processes, delivering exceptional purity, optimized yields, and improved economic viability. This article explores how sequential SFE to PLE workflows are redefining extraction in industries ranging from nutraceuticals to environmental analysis.

Understanding Supercritical Fluid Extraction (SFE)

At the heart of SFE is the unique behavior of supercritical CO₂. When carbon dioxide is pressurized above 74 bar and heated beyond 31°C, it enters a supercritical state where it behaves as both a gas and a liquid. This hybrid nature allows CO₂ to diffuse like a gas while dissolving substances like a liquid, making it an outstanding solvent for non-polar and moderately polar compounds.

Key advantages of SFE include:

- Minimal solvent residues in the final product

- High selectivity through tunable pressure and temperature

- Lower environmental impact compared to organic solvents

By adjusting parameters such as pressure, temperature, and the addition of co-solvents like ethanol, operators can precisely target compounds ranging from lipids and essential oils to bioactive terpenes.

Pressurized Liquid Extraction (PLE): Complementary Strengths

While SFE excels in extracting non-polar components, PLE shines when targeting more polar analytes. Also referred to as accelerated solvent extraction, PLE uses liquid solvents heated beyond their boiling points while maintaining them under pressure to prevent vaporization. This combination significantly improves mass transfer, reduces viscosity, and enhances solvent penetration into the matrix.

Typical advantages of PLE include:

- Shorter extraction times—often just minutes per cycle

- Reduced solvent consumption

- Compatibility with in-cell clean-up using adsorbents

By fine-tuning solvent polarity, temperature, and extraction duration, PLE can be customized for a wide range of polar compounds, from phenolic antioxidants to flavonoids.

Why Combine SFE and PLE Sequentially?

Despite the individual strengths of SFE and PLE, no single technique universally extracts the full spectrum of valuable components from complex matrices like botanical biomass or agro-industrial residues. Sequential SFE–PLE pipelines address this gap by leveraging the selectivity of each process in a structured sequence.

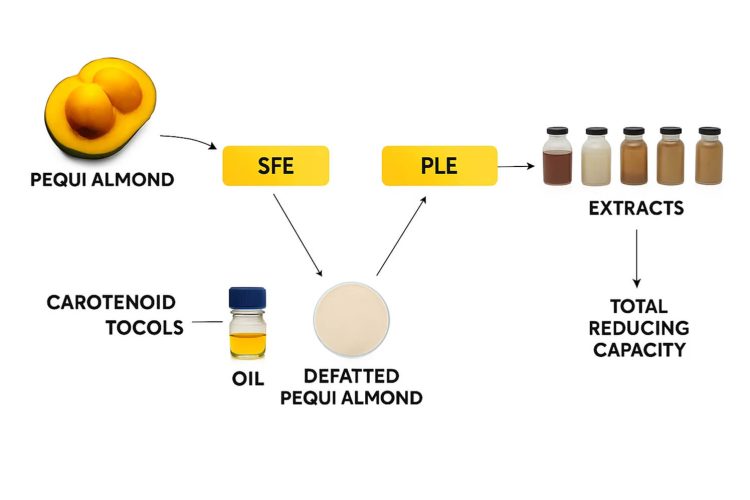

Consider this typical workflow:

- Stage 1: SFE with CO₂ – The process begins by extracting non-polar lipophilic compounds under supercritical conditions. This stage recovers essential oils, carotenoids, or fatty acids while leaving behind more polar constituents.

Stage 2: PLE with polar solvents – After SFE, the same biomass undergoes PLE using ethanol-water mixtures or other polar solvents to recover phenolics, alkaloids, and other hydrophilic compounds.

This approach not only broadens the range of recoverable analytes but also improves overall extraction efficiency and purity by fractionating compounds according to polarity.

Real-World Applications of Multistage Pipelines

Several case studies underscore the practical impact of sequential SFE–PLE extraction strategies:

- Passion Fruit Bagasse – Researchers have demonstrated that a multistage SFE–PLE process could recover up to four distinct fractions, including oils, pigments, and polyphenols, with higher yields than single-stage extractions. An economic assessment revealed this method offered superior cost-effectiveness and product value.

Hemp and Cannabis Extracts – Sequential pipelines enable precise fractionation of cannabinoids, terpenes, and flavonoids. The initial SFE stage isolates non-polar cannabinoids and volatile terpenes, while the PLE stage extracts residual polar phytochemicals for enhanced bioactivity profiles. - Environmental Sample Clean-Up – In analytical settings, sequential SFE–PLE has been applied to isolate persistent organic pollutants and separate them from matrix interferences with improved selectivity.

These examples highlight the broad applicability of multistage pipelines across food, pharmaceutical, and environmental sectors.

Optimizing Process Parameters

Designing an effective SFE–PLE pipeline requires a meticulous understanding of process variables. Each stage must be tuned to the target compounds and raw material characteristics.

Key parameters in SFE:

- Pressure: Higher pressures increase CO₂ density and solvency but may co-extract undesired waxes.

- Temperature: Elevated temperatures raise solute vapor pressure but reduce CO₂ density.

- Co-Solvent Percentage: Small additions of polar co-solvents improve the solubility of moderately polar compounds.

Critical considerations in PLE:

- Solvent Selection: Ethanol-water blends or acetone are common choices for their polarity and safety profiles.

- Temperature and Time: Higher temperatures (up to 200°C) accelerate extraction kinetics.

- In-Cell Adsorbents: Materials such as silica or alumina can trap interfering substances, improving extract purity.

Optimizing these parameters ensures each stage contributes to the desired purity and yield without compromising downstream processing.

Inline Purity Enhancement and Analytical Couplings

Another powerful dimension of multistage pipelines is the ability to couple extraction stages directly to analytical or preparative chromatography. By connecting SFE or PLE outputs to liquid chromatography (LC) or gas chromatography (GC) systems, operators can achieve real-time fractionation and quantification.

For example:

- SFE–LC Coupling: Supercritical CO₂ effluent can be depressurized and directed onto LC columns for immediate separation of complex mixtures.

- PLE–GC Coupling: Solvent extracts can be injected into GC systems to analyze volatile compounds or confirm purity.

This inline strategy streamlines workflows and reduces the risk of degradation or contamination between extraction and analysis.

Economic and Environmental Considerations

While the capital costs of SFE and PLE equipment are higher than traditional Soxhlet extractors, the long-term economic and environmental benefits often justify the investment:

- Reduced Solvent Use: CO₂ is recyclable, and PLE consumes less solvent per gram of extract.

- Lower Energy Consumption: Faster extractions translate to decreased heating and operational times.

- Higher Yields and Purity: Better selectivity reduces the need for extensive downstream purification.

An economic evaluation of sequential pipelines applied to passion fruit bagasse demonstrated higher net profits and lower production costs compared to single-stage processes, especially when targeting high-value fractions.

Challenges and Solutions in Scaling Multistage Pipelines

Despite the clear advantages, implementing sequential SFE–PLE pipelines poses challenges:

- Technical Complexity: Managing multiple high-pressure systems requires specialized knowledge and rigorous safety protocols.

- Process Integration: Designing smooth transitions between stages demands careful engineering.

- Optimization: Fine-tuning extraction parameters for different matrices can be time-intensive.

Solutions include:

- Automation: Modern extraction platforms feature programmable controls and monitoring systems to simplify operation.

- Standardized Protocols: Developing validated procedures reduces variability and training requirements.

- Pilot-Scale Trials: Conducting small-scale studies before full-scale production helps refine parameters and anticipate operational issues.

With thoughtful planning, these obstacles can be effectively managed, enabling scalable, high-purity extraction pipelines.

Sequential SFE to PLE: Multistage Purity Pipelines (Part 2)

Strategic Design of Multistage Extraction Pipelines

Building a successful sequential SFE–PLE pipeline starts with a clear understanding of the target compounds and their chemical characteristics. Designing the extraction sequence requires answering a few critical questions:

- Which fractions are most valuable? For instance, terpenes and cannabinoids command premium prices in cannabis extracts, while phenolics and pigments are key in nutraceuticals.

- What is the polarity distribution? This informs the order of SFE and PLE stages and guides solvent selection.

- How stable are the compounds? Thermal degradation must be considered when setting temperatures.

A typical design strategy includes:

- Sample Preparation: Grinding and drying the biomass to ensure uniform particle size and moisture content, which improves extraction kinetics.

- Stage 1 SFE: Applying optimized pressure and temperature conditions, often starting with pure CO₂ to extract volatile oils, then adding a co-solvent if moderately polar compounds are targeted.

- Intermediate Handling: Depressurizing and removing the SFE-extracted fraction while ensuring minimal exposure to oxygen or light.

Stage 2 PLE: Selecting a solvent system matched to remaining polar constituents and applying controlled heating cycles. - Post-Processing: Evaporation of solvents, polishing via filtration, or inline chromatography for further refinement.

This structured approach reduces cross-contamination between fractions and maximizes the economic value of each extract.

Regulatory and Quality Considerations

In regulated industries like pharmaceuticals and nutraceuticals, extraction processes must meet stringent quality and traceability standards. Implementing a multistage SFE–PLE pipeline requires validation against parameters such as:

- Residual Solvents: CO₂ leaves no residue, while PLE solvents must be efficiently removed.

- Purity and Potency: Analytical testing verifies that the extract meets specifications for active compounds and contaminants.

- Batch Consistency: Repeatability of yields and composition is critical for regulatory compliance.

Quality management systems incorporating Hazard Analysis and Critical Control Points (HACCP) or ISO 22000 can help maintain high standards across the pipeline.

Sustainability Benefits of Sequential Pipelines

One of the most compelling arguments for multistage extraction pipelines is their alignment with sustainability goals. Compared to traditional solvent extraction, sequential SFE–PLE pipelines offer:

- Lower Carbon Footprint: CO₂ used in SFE is often reclaimed industrially, and solvent recycling further reduces emissions.

- Reduced Waste: Selective extraction minimizes the production of undesired byproducts and simplifies disposal.

- Energy Efficiency: Faster processing and integration of stages lower total energy requirements.

These advantages support a circular economy approach, turning agricultural byproducts and plant biomass into valuable extracts while conserving resources.

Future Directions in Multistage Extraction

Research and technological innovation continue to expand the capabilities of sequential SFE–PLE systems. Promising areas of development include:

- Advanced Process Control: Artificial intelligence and machine learning are being applied to predict optimal extraction parameters and adapt them in real time.

Novel Solvents: Deep eutectic solvents and greener alternatives to traditional organics are being evaluated for PLE stages. - Hybrid Systems: Integration of ultrasonic or microwave assistance is enhancing extraction efficiency and selectivity.

These innovations are likely to further reduce costs, improve yields, and open new possibilities for extracting complex natural products.

Conclusion: A New Standard in Extraction Purity

Sequential SFE–PLE pipelines exemplify the convergence of green chemistry, process engineering, and economic viability. By combining the precise selectivity of supercritical CO₂ with the versatility of pressurized liquid solvents, these multistage systems deliver unmatched purity and yield.

From botanicals to industrial byproducts, multistage pipelines are transforming how high-value extracts are produced. As regulatory frameworks tighten and consumer demand for clean-label products grows, the adoption of these integrated workflows is poised to accelerate.

For organizations aiming to lead in quality, sustainability, and profitability, investing in sequential SFE–PLE extraction is more than a technical upgrade—it’s a strategic imperative.

Sources

- Supercritical Fluid Extraction — Wikipedia

- Foods MDPI — Advances in Pressurized Liquid Extraction (MDPI)

- Molecules MDPI — Supercritical CO₂ Extraction Review (MDPI)

- Recent Advances in Pressurized Fluid Extraction (Chromatography Online)

- Passion Fruit Bagasse Extraction Economics (ResearchGate)

- Analytical Chemistry — SFE Coupling (ACS Publications)

- MDPI — Biorefinery Applications (MDPI)

- ScienceDirect — SFE Applications (ScienceDirect)