Remediating heptane-extracted crude is something the food industry has been doing for decades. Heptane has long been used in the extraction of castor and other vegetable oils. The American Chemical Society and Royal Academy of Chemistry categorized the use of heptane as green chemistry. [1]

Being considered green chemistry means heptane is less toxic than other solvents and it meets specific environmental and health standards. It’s no wonder more extractors are turning to heptane, but what are the best methods to remediate heptane from your crude?

What is Heptane?

Heptane is an organic non-polar solvent, less dense than water and immiscible in it. It is a colourless liquid at room temperature with a petroleum-like odour. [2] Heptane is a straight-chain alkane with seven carbon atoms. Extractors like heptane because it is a safer alternative than hexane, being less toxic and less volatile. [3] Nevertheless hexane is less dense than heptane so it can be used for a wider variety of applications.

How to Remediate Heptane?

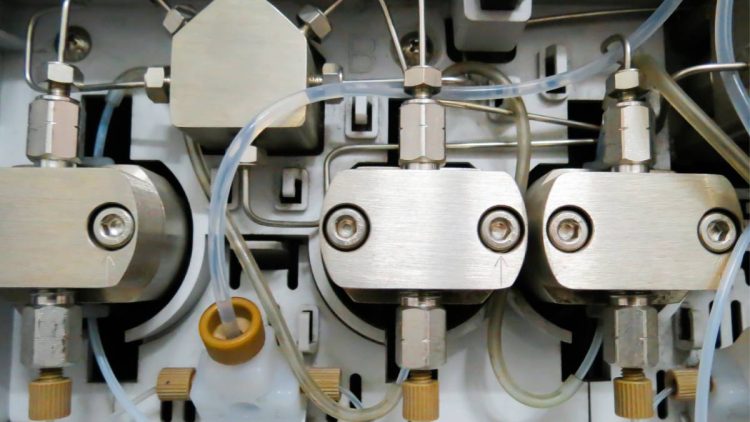

There are a few methods extractors can use to remediate heptane. Three common ways to remove this kind of solvent from the crude extract are by using Centrifugal Partition Chromatography (CPC), High Performance Liquid Chromatography (HPLC) and Simulated Moving Bed (SMB) chromatography.

In order to obtain a purer product these processes can be repeated on the crude extract, allowing the removal of solvents, toxins, pesticides, heavy metals or unwanted substances. [4]

Centrifugal Partition Chromatography (CPC)

CPC is a liquid-liquid chromatography that can be used to remediate heptane. It is one of many methods categorized under Counter Current Chromatography (CCC). Some extractors choose CPC over HPLC and other methods because of its versatility. Changing the application requires the replacement of solvents in the two liquid phases.

High Performance Liquid Chromatography (HPLC)

HPLC, on the other hand, may involve more changes, like altering the stationary phase. When compared to CPC, extracts using HPLC have a much higher resolution, meaning that it is possible to obtain better separation of substances during the chromatographic process. The process is also highly scalable for mass production. Many extractors choose HPLC for these reasons.

Simulated Moving Bed (SMB)

Remediating heptane with SMB differs quite a bit from CPC and HPLC. SMB is a continuous process where the starting material is “pumped continuously and the final fractions are also collected continuously. This allows to scale-up the cannabinoids purification to very high throughputs, over hundreds of liters per day”. [3] Maximizing daily output is one of the top reasons why extractors choose SMB.

Deciding which one of these heptane-remediation methods is the best for your operation comes down to equipment, cost, and preference. Smaller operations that don’t need to produce hundreds of liters per day can start with CPC. Then you can either upgrade to HPLC or SMB in the future, when the need to scale arises, or start with either method from the beginning to produce extracts with higher purity.

References:

[1]Talk Nerdy With Us. 710 Spirits Extraction Products. https://710spirits.com/tell-me-more/

[2] https://pubchem.ncbi.nlm.nih.gov/compound/Heptane

[3] Buddrick, O. et al. Heptane as a less toxic option than hexane for the separation of vitamin E from food products using normal phase HPLC, RSC Advances, (2013); 3(46), 24063–.doi:10.1039/C3RA44442B [Journal impact factor = 3.361] [Times cited = 20]

[4]Solutions For Processing and Cannabis Analysis. Paralab. P 18-19. https://paralab.es/wp-content/uploads/2020/08/CanabinoidesV4_versao_digital.pdf

Image: Heptane Remediation Methods by Green House Healthy