Hashish — or hash — is a product derived from cannabis that’s made by compressing and processing the plant’s trichomes. Some DIY hash producers may have an at-home setup to produce hash, though the type of production and distribution needed for large-scale needs typically requires more sophisticated — and expensive — equipment.

Using the same basic principles as at-home producers, large-scale hash companies use automated extraction and processing equipment that can yield large quantities of high-quality hash on a commercial scale.

Here are some examples of commercial hash equipment used on an industrial scale.

Small Bubble Hash Machines

Stainless steel bubble hash machines are designed to accommodate large quantities of plant material using medical-grade stainless steel. An example is Wacky Willy’s Rocket Tank 17G, which uses the force of carbon dioxide (CO2) or compressed air to disturb the flower and removes plant trichome heads using ice and water.

This equipment can accommodate anywhere from 6 to 17 gallons on average and can help boost return on investment (ROI) on hash yields. Equipment like this can cost upwards of roughly $1,000.

Large Hash Washers

Industrial grade hash washers make producing large quantities of potent hash easier and more efficient. They’re easy to clean and maintain, making them ideal for commercial purposes. Given the high-tech nature of these commercial grade hash washers, expect to spend upwards of $15,000. Examples include the Rosin Tech Hash Washer Pro, which can hold 1.5 pounds of plant material per cycle and includes a 20-gallon reclaim tank. The Bruteless Commercial Hash Washing System (see image) can tackle 15,000 grams of fresh frozen flower per run and features a cryogenic insulation sleeve to keep ice frozen longer. Whistler Technologies manufactures a system that requires bay doors and high ceilings to accommodate equipment that can run 160,000 grams of fresh frozen flower.

Ice Hash Screeners

Ice hash screeners can be used with ice hash washers to remove trichomes. Cannabis is first mixed with ice water in an agitated tank to promote the swelling of non-cannabinoid organics and the falling off of the trichomes.

The mixture is then fed into the ice hash screener to remove the biomass and separate the water from the trichomes. The trichomes are pressed to eliminate excess water and set to dry. ABM Equipment makes 24” diameter and 40” diameter screeners, both with five screens and powered by an 1800 RPM motor.

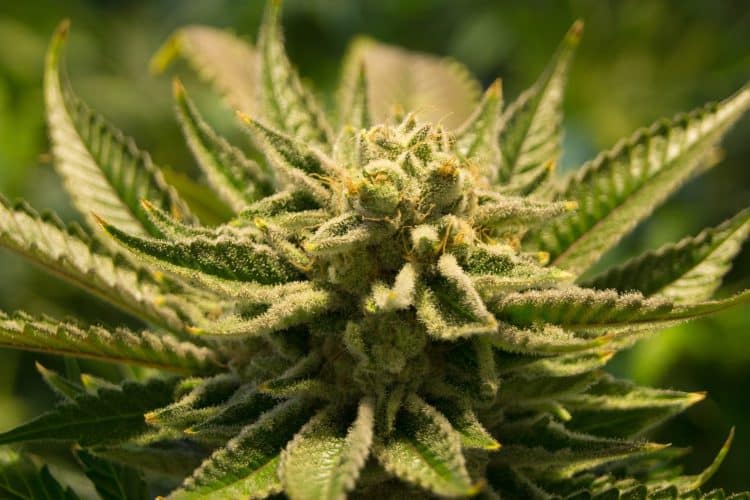

Image source: futurefilmworks via Pixabay