Crude oil and petroleum production generates significant pollution. This includes cancer-causing air emissions and toxic wastewater subject to state and federal regulation. Industrial sites often also harbor contaminated soil. Soil poisoned by oil and petroleum poses a threat to plants, animals, and people. [1] Conventional solutions like landfill disposal or incineration are expensive and lead to residual pollution (e.g., air pollution). Biological remediation is another possibility, such as using spent mushroom compost [2], but this route is relatively time consuming (requiring months). Scientists recently confirmed a third possibility for soil remediation: supercritical carbon dioxide (CO2) extraction. [1]

Supercritical CO2 represents a strategy that is cleaner than traditional methods and more efficient than biological remediation. The present study [1] investigated various extraction conditions to optimize the remediation of soil contaminated with crude oil.

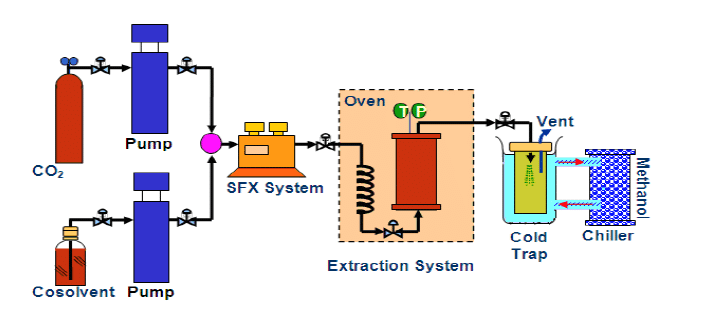

The researchers sourced crude oil from an oil field in the United Arab Emirates. They spiked soil samples at 10% w/w for analysis and implemented a 24-factor experiment to look at different extraction variables. These included pressure (250 or 250 bar), temperature (80 and 160ºC), flow rate (1 and 4 ml/min), and co-solvent. In terms of co-solvent, they looked at CO2 without a co-solvent as well as 5% toluene or 5% n-heptane. The two co-solvents were chosen due to “high solvency for hydrocarbons.” The extraction system is pictured below.

Al-Marzouqi AH, Zekri AY, Azzam AA, Alraeesi AY. Optimization of supercritical fluid extraction of hydrocarbons from a contaminated soil: an experimental approach. International Journal of Environmental Science and Development. 2019;10(10). CC BY 4.0

They determined the highest efficiency at 350 bar, 80ºC, 1 ml/min, and 5% n-heptane. This condition was capable of “extracting gasoline and diesel range hydrocarbons.” Though less efficient, the same conditions (temperature, pressure, and flow rate) paired with toluene or no solvent were similarly effective at liberating contaminants. The researchers explained that the high pressure likely masked the additional solvating power from n-heptane or toluene. Flow rate did not have a statistically significant impact, and the researchers encouraged operation at 4 ml/min.

Pure supercritical CO2 (no co-solvent) at 350 bar and 80ºC pulled almost 93% of the petroleum hydrocarbons from the contaminated soil. That said, the researchers refined their analysis to look at 16 particularly noxious compounds known as polycyclic aromatic hydrocarbons (PAHs; e.g., naphthalene). In this case, they had to crank the temperature up to 160ºC for optimal extraction, explaining that it may be necessary to volatilize the PAHs with higher temperatures to make them more soluble.

Overall, they conclude, “Supercritical fluid extraction proved to be an efficient method for the

remediation of hydrocarbon-contaminated soil.” Supercritical CO2 is already praised for sustainable botanical extraction; its ability to remediate toxic compounds from the Earth adds to the impressive power of this technology.

References

1- Al-Marzouqi AH, Zekri AY, Azzam AA, Alraeesi AY. Optimization of supercritical fluid extraction of hydrocarbons from a contaminated soil: an experimental approach. International Journal of Environmental Science and Development. 2019;10(10). [Impact Factor: 0.388; Times Cited: n/a]

2- Mohammadi-Sichani MM, Assadi MM, Farazmand A, Kianirad M, Ahadi AM, Ghahderijani HH. Bioremediation of soil contaminated crude oil by Agaricomycetes. J Environ Health Sci Eng. 2017;15:8. doi:10.1186/s40201-016-0263-x. [Impact Factor:2.179; Times Cited: 14 (Semantic Scholar)]