Solanesol is a terpenoid that occurs naturally in a variety of common plants, including tobacco, tomato, pepper plants, and eggplants. It is an effective anti-fungal, antibacterial, anticancer, and anti-inflammatory compound. In the pharmaceutical industry, solanesol is widely used to synthesize ubiquinone drugs, including coenzyme Q10 and vitamin K2.

Extracting solanesol from tobacco leaves (tobacco is the main source of solanesol) can be accomplished in several different fashions. The most prominent include ammonia leaching pretreatment-assisted extraction, dynamic saponification extraction, ultrasonic-assisted extraction, molecular distillation, supercritical fluid extraction, bio-enzymatic extraction, and molecular imprinted polymers extraction. [1]

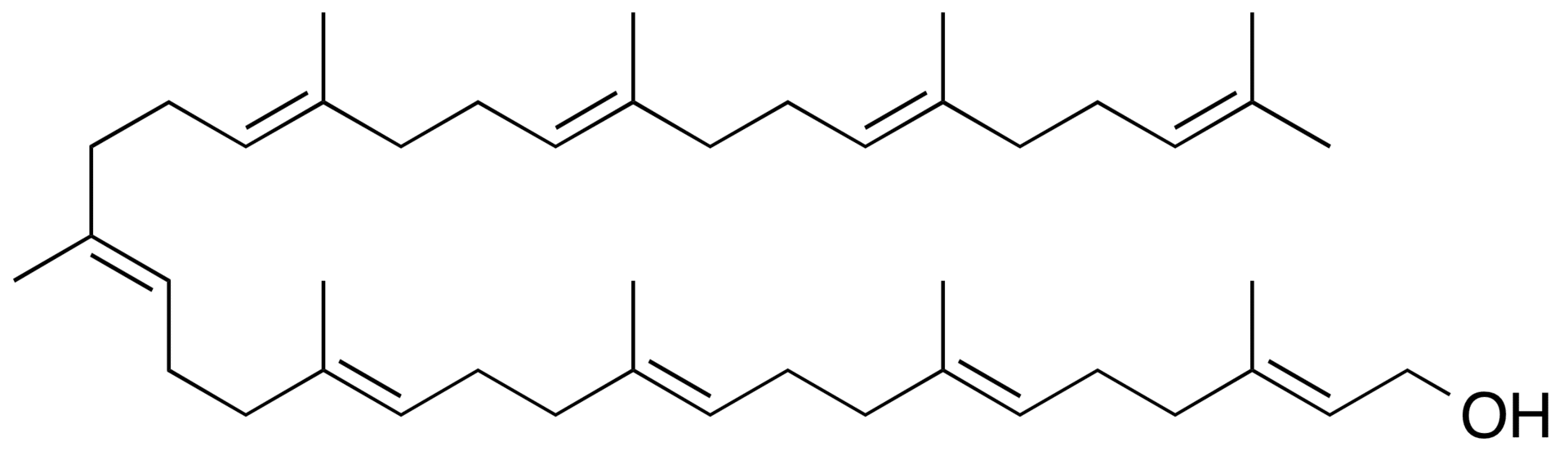

Solanesol. Public Domain.

Ammonia leaching pretreatment increases extraction yields when it’s performed prior to extraction with hexane as the solvent. The leaching deteriorates the cell walls of the tobacco leaves and converts solanesol ester into free solanesol through saponification and hydrolyzation. Additionally, the treatment increases the purity of the extract and shortens the equilibrium time of extraction. [1]

Dynamic saponification extraction employs solvents ethanol and naphtha to extract solanesol through saponification. Optimal parameters are cited [2] as follows: naphtha, sodium hydroxide in 80% ethanol, a 1:4 ratio of sodium hydroxide to tobacco extract, and a saponification reaction time of 2.5 hours. This increases yield by about 9% and solanesol by about 3% over conventional saponification methods [2]. Dynamic saponification also uses fewer experimental procedures and causes less consumption of solvent, making it faster and more efficient than conventional saponification.

Ultrasonic-assisted extraction using acetone as the solvent leads to reduced extraction times, increased efficiency, and a simplified extraction procedure. One experiment optimized this procedure at 60º C over a two-hour period with 160 W ultrasonic power. Under these conditions, the extraction yield of solanesol can reach about 95%. [3]

Molecular distillation is performed under high-vacuum conditions to refine crude solanesol extract without pretreatment. The result is a highly pure and high-yielding solanesol extract. According to one optimizing experiment using wiped-film distillation, the purity of the resultant extract could be as high as 98%, and the yield could reach 77%. [4]

Supercritical fluid extraction requires a short extraction time and a relatively low extraction temperature. In an experiment using supercritical carbon dioxide (CO2) at a pressure of 20 MPa (200 bar), ethanol as a co-solvent, an extraction temperature of 55º C, and an extraction time of 1.5 hours, the result was crude solanesol consisting of 30% mass fraction. This then underwent silica gel column chromatography and recrystallization, which resulted in a mass fraction of more than 98%. [5]

With bio-enzymatic extraction, an enzyme is used to degrade the cell walls of the plant source, facilitating the extraction. Cellulase and ligninase at a ratio of 15:1 were used in one experiment utilizing a water to tobacco ratio of 5:1. The result was an average extraction yield of about 97%. [6]

Molecular imprinted polymers (MIPs) extraction is effective at yielding highly pure solanesol. MIPs are synthetic receptors for a given molecule, in this case solanesol. In an experiment [7] carried out under optimal chromatographic conditions, a product of 98% purity resulted; the yield was 2.5% of the dry weight of the tobacco leaves.

Thus, there are numerous effective methods for the extraction and purification of solanesol, an important terpenoid with myriad medical applications.

Image Source: https://www.hippopx.com/en/tobacco-green-dried-353862

References:

- Ning Yan, et al. Bioactivities and medicinal value of solanesol and its accumulation, extraction, technology, and determination methods. 2019;9(8):334. [Impact Factor: 4.694; Times Cited: 8 (Semantic Scholar)]

- Zhao C, et al. Extraction of solanesol by dynamic saponification method. Chemical Engineering. 2007;35:9–12. [Impact Factor: 10.652; Times Cited: 2 (Semantic Scholar)]

- Zhang Z, Feng X. Study on ultrasonic assisted extraction of solanesol from tobacco leaves. J Food Sci Biotechnol. 2007;26:51–53. [Impact Factor: 1.513; Times Cited: 1 (Semantic Scholar)]

- Qian C, Zhang J. The study of refining solanesol by molecular distillation. J Chem Eng Chin Univ. 2009;23:275–278. [Impact Factor: 2.627; Times Cited: 1 (Semantic Scholar)]

- Wei H, et al. Extraction and separation of solanesol from Nicotiana tobacum by supercritical fluid extraction and silica gel column chromatography. Chin Tradit Herb Drugs. 2005;36:690–692. [Impact Factor: 0.219; Times Cited: 3 (Semantic Scholar)]

- Wang X, et al. Improved extraction of solanesol from tobacco waste by enzymatic cell wall breaking. Chin J Biotechnol. 2013;29:1706–1710. [Impact Factor: n/a; Times Cited: 5 (Semantic Scholar)]

- Ma X, et al. Solanesol extraction from tobacco leaves by flash chromatography based on molecularly imprinted polymers. J Chromatogr B. 2016;1020:1–5. [Impact Factor: 3.004; Times Cited: 14 (Semantic Scholar)]