Conventional methods of extraction which use traditional solvents or carbon dioxide (CO2) have marked major steps in the development of the extraction field. They also come with various limitations.

EAE: What is it and how green it really is?

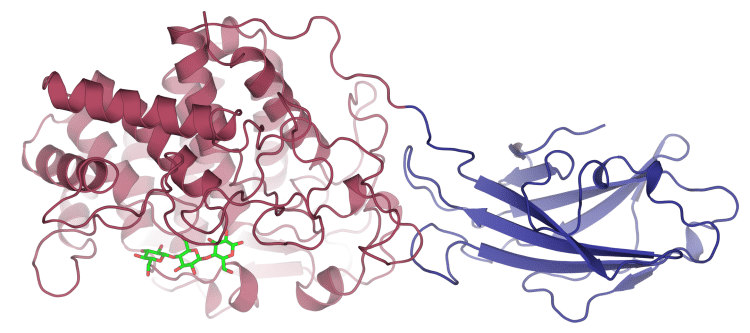

Enzyme-assisted extraction (EAE) is a green approach that’s seen as a viable alternative or addition to conventional methods. [1] The most widely employed enzymes for the purposes of extraction are cellulases, hemicellulases, and pectinases. They come predominantly from bacteria and fungi but can also be derived from animal organs and vegetable and fruit extracts.

EAE is based on enzymes’ ability to hydrolyze and disrupt cell walls, providing access to the compound of interest behind them. Extractors need to know the structure of the cell walls they’re going to hydrolyze to choose the right kind of enzymes. For example, if the raw material is a plant whose cell walls tend to consist of cellulose fibers, hemicelluloses, and pectic substances, all linked to a structural protein, the complete enzyme preparation would need to contain cellulases, hemicellulases, pectinases, and proteases.

EAE Advantages & Limitations

The advantages of EAE include higher yields which are directly attributed to the breaking down of cell walls. The selectivity makes for higher purity. Other benefits include high catalytic efficiency, preservation of natural products’ original efficacy, reduced time of extraction, and lower volume of solvent required.

EAE can be applied to plants, bacteria, fungi, algae, and animals to obtain oils, proteins, carbohydrates, and phenolics. EAE can also be coupled with other methods and techniques, such as three-phase partitioning and the use of microwave, ultrasound, and supercritical CO2.

Commercial Scale EAE Extraction?

Adopting EAE on a commercial scale may present a cost-effectiveness issue. Potential solutions include:

- Lower cost to produce enzymes

- Protein and genetic engineering to improve enzyme performance

- Enhanced enzyme immobilization techniques

Wine production utilizes pectinases and glucanases for superior color extraction and overall quality, and commercial enzyme preparations are available. [1] Another example regards silymarin compounds from milk thistle, which may be efficiently extracted with 50% ethanol (1:6 solid-solvent ratio), 30 U/mg cellulase, and 180 W ultrasound power for 2 hours. [2] EAE and ultrasonic-enzyme-assisted extraction may also be used for polysaccharides from cup plant; in this case, cellulase, pectinase, and papain can be used.

Reference:

- Marathe et al. Chapter 8: Enzyme-assisted extraction of bioactives. In: M. Puri, ed. Food Bioactives. Springer International Publishing; 2017:171-201. Times Cited: 17 (Semantic Scholar)

- Zhao F, Li X. Ultrasonic-assisted enzymatic extraction of silymarin from the Silybum marianumseed shell and evaluation of its antioxidant activity in vitro. EXCLI J. 2015;14:861-874. doi:10.17179/excli2015-257. [Impact Factor: 2.837; Times Cited: 2 (Semantic Scholar)]

Image Credit: Cellulase, B.T.Riley, Wikipedia, CC BY-SA 4.0