The pace of modern progress can be staggering. New innovations and technologies allow for greater capabilities across the board in many industries. And as the cannabis extraction industry continues to grow, so does its onward push toward progress. Automation in the extraction process is one avenue worth examining in this regard.

Automation generally follows the steady success of an industry. More demand creates the need to keep up—quickly. The global cannabis extract market is projected to grow at a compounded rate of 16.6%, reaching around $23.7 billion in 2027. Those numbers directly coincide with an increase in supply, and to achieve this potential, automated aspects of the production and supply chains are essential. Automation helps reduce costs, improve product quality, and keep the operation safe.

Let’s take a linear look at the seed to sale process to see how automation can help facilitate the entire product pipeline.

- Planting/Harvesting – Automation in the agricultural end of cannabis production begins with machines that can plant and harvest vast amounts of cannabis and hemp. From tractor attachments that pluck plants from the ground to industrial trimmers, what once was done by hand, machines now accomplish instead.

- Automated Extraction Equipment – Once the raw plant matter has been harvested, it’s on to actual extraction. While aficionados all have their favorite method, large-scale operations generate mass commercial product by utilizing extraction equipment that automates the process. Specialty companies offer industrial-scale automation to allow businesses to keep scaling up. Automated systems integrate extraction and separation units, solvent recovery systems, and heating and cooling solutions to streamline the manufacturing process each and every step of the way. Equipment manufacturers such as Apeks Supercritical and Thar Process (among others) offer contained closed-loop extraction systems with full automation.

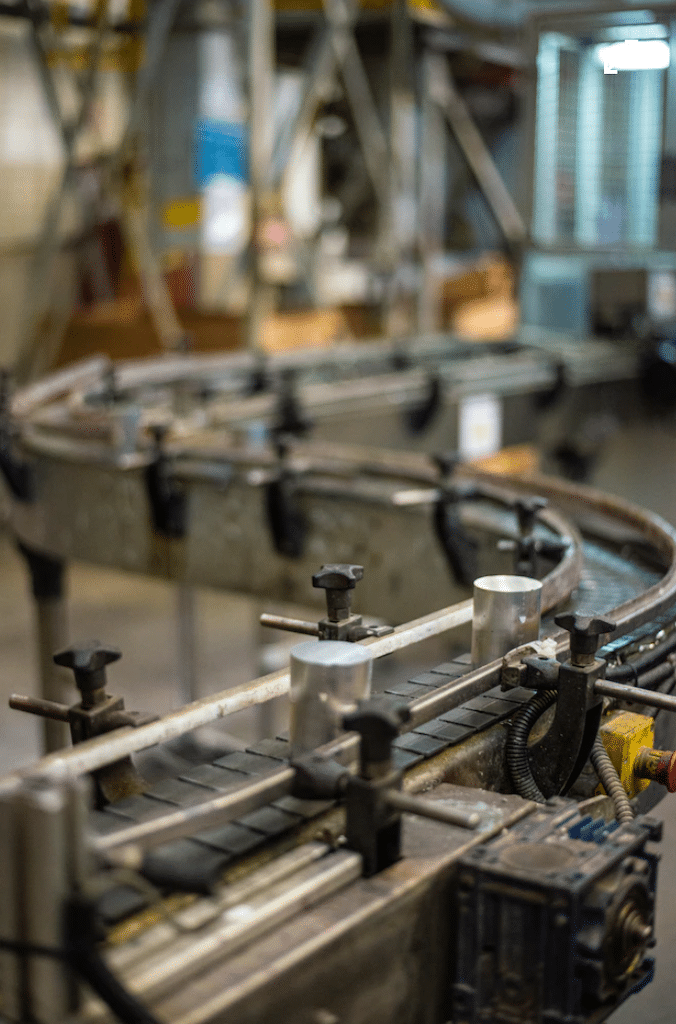

- Packaging/Labeling – After the actual extraction has been completed and/or the extract has been turned into an end product, automated equipment packages and labels concentrates through the end of the process. This is similar to any product manufacturing process with conveyor belts of bottles, tubes, or any other container that can be filled, sorted, and labeled by tireless machines.

Automation can help push the cannabis extraction process forward to meet huge global demand. As new techniques and technologies develop, look for automation options available at each level to continue to expand.

Image source: Remy Gieling courtesy of Unsplash