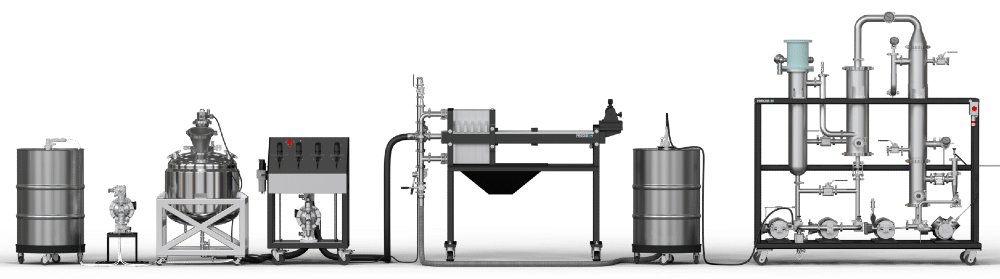

Opportunity abounds in the nascent hemp and cannabidiol (CBD) market. To keep up with demand, growers and manufacturers continually refine their purification techniques. Precision Extraction recently launched T-SEP and L-SEP, two patent-pending processes designed to increase efficiency and lower costs.

T-SEP, short for tetrahydrocannabinol (THC) separation, produces high-quality, THC-free CBD distillate. Strict regulations protecting hemp and CBD sales prohibit products containing more than 0.3% THC.

“T-SEP is a process of THC remediation for CBD oil. Hemp plants inherently contain a bit of THC, which becomes concentrated during extraction. This is a problem because you need to have a low, if not non-detectable level of THC in your CBD products,” explains Nick Tennant, Precision Extraction’s managing director.

“Traditional means of processing CBD oil, such as flash chromatography, are extremely costly to run. The T-SEP’s solvent-based process costs about $3.50 per liter compared to about $350 per liter with traditional methodology.”

The T-SEP Model 7LPH can process up to seven liters of crude hemp oil per hour. Precision Extraction states that over 99% of THC/THC-A can be removed. CBD manufacturers can save money as well as ensure that their oil meets regulatory concerns.

Precision has also introduced the revolutionary L-SEP process. L-SEP stands for lipid separation. The process is similar to that behind T-SEP, except it removes fatty lipids rather than THC.

“Basically,” Tennant says, “if you’ve ever touched a cannabis leaf, a maple leaf, etc., you can feel that waxy consistency that rubs off on your fingers. That’s due to various lipids that the plant naturally produces to protect itself from predators and the environment.”

When you extract cannabinoids like CBD from hemp and cannabis, the lipids are extracted as well. Manufacturers don’t want this to happen because it affects the quality of the final product. As Tennant explains: “Imagine burning olive oil in a pan. It doesn’t smell good. It doesn’t taste good. Nobody would smoke something like that, right? So those lipids become an undesirable component of the extraction process and need to be removed.” Inhaling lipids can also cause health issues.

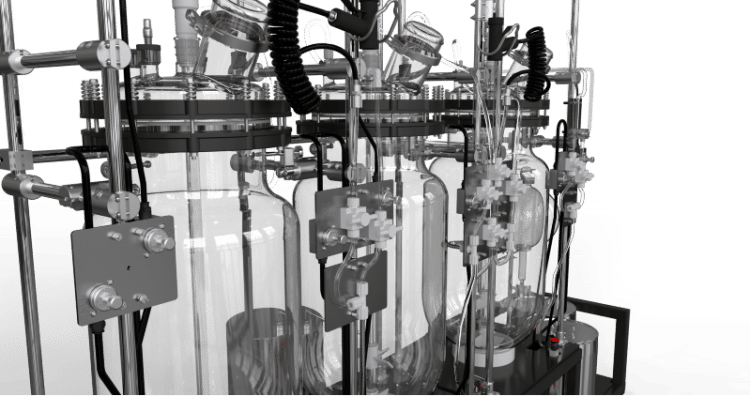

This is where L-SEP is useful. With traditional methodologies, like ethanol-based winterization, the extraction is submerged in ethanol and chilled for 24+ hours before being filtered. L-SEP is a similar process, but it occurs at room temperature and uses a proprietary solvent blend. A company utilizing this technology won’t have to worry about expensive refrigeration or temperature control costs.

“We’ve taken a process that would normally take 24 hours and a lot of energy to cool everything down, and we’ve done it with no cooling energy, and we’ve done it in five to seven minutes. That’s what the L-SEP does,” says Tennant.

The L-SEP 60LPH can process up to 60 liters of crude cannabis or hemp oil per hour. The price is less than 50 cents per liter. The company reports that 97% lipid removal is achieved in less than ten minutes.

While T-SEP and L-SEP have proprietary elements (the secret sauce), both products represent the kind of new technology fueling growth in the hemp and cannabis industries. Companies that utilize either process can trim costs and maximize their product refinement throughput.