Supercritical carbon dioxide (CO2) extraction is one popular method for the commercial extraction of cannabis. In 2020, Australian researchers investigated supercritical CO2 extraction strategies to “obtain a GMP license to produce pharmaceutical grade medicinal cannabis” and “optimise the process for extraction of cannabis material at a pharmaceutical scale.” [1] Notably, they avoided using any co-solvent (i.e., ethanol) to make the process simpler from a regulatory standpoint and cleaner from a product standpoint.

The investigation was organized using design of experiments (DOE), a Good Manufacturing Practice (GMP)-approved approach to process development that allows the user to analyze how multiple factors interact and affect outputs. [1,2] The factors in this case were extraction parameters [1]:

- CO2 Flow Rate (40-150 g/min)

- Pressure (150-320 bar)

- Time (4-10 hours)

And the outputs were yield parameters:

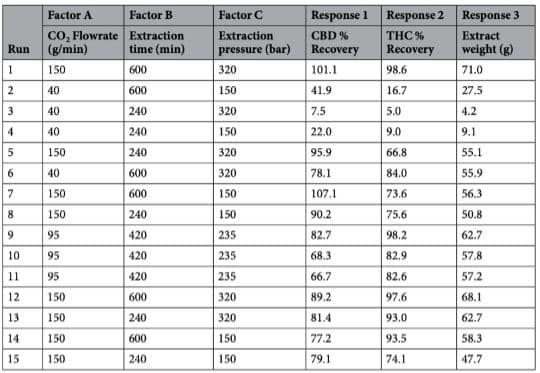

They set the temperature at 60º C, reportedly to match the equipment manufacturer’s (Waters) recommendation. The Victorian State Government provided cannabis biomass from multiple chemovars with a total CBD:THC ratio of 1:1.5. The researchers packed 1.0 kg of the biomass for each run. The results are summarized in the table below, reprinted from the open-access study.

Reprinted from: Rochfort S, Isbel A, Ezernieks V, et al. Utilisation of Design of Experiments Approach to Optimise Supercritical Fluid Extraction of Medicinal Cannabis. Sci Rep. 2020;10(1):9124. doi:10.1038/s41598-020-66119-1. License: Creative Commons Attribution 4.0 International.

Run #1, with high flow rate (150 g/min), high pressure (300 bar), and a long extraction time (10 hours), dominated the chart in terms of yield for both cannabinoid recovery and extract weight. Flow rate was the most impactful factor overall, followed by time and then pressure. THC recovery depended more significantly on time compared to CBD recovery or weight.

There were unique CBD:THC ratios depending on extraction parameters. Runs #6 and #7 illustrate this point with similar extract weights but unique CBD:THC ratios. If the biomass were hemp, the study authors reason, “this method may be optimised further so that low levels of THC could be removed.”

The study did not account for lipids and other unwanted plant materials, which factor heavily into extract weight. The process would also require adjustment for specific chemovars. [1] Although the procedure might not appeal to every extractor, it does illustrate a methodological approach that is likely to become increasingly relevant as international cannabis operators pursue GMP standards.

References

- Rochfort S, Isbel A, Ezernieks V, et al. Utilisation of design of experiments approach to optimise supercritical fluid extraction of medicinal cannabis. Sci Rep. 2020;10(1):9124. doi:10.1038/s41598-020-66119-1 [Impact factor: 3.998; Times cited: n/a]

- Türeli NG, Türeli AE. Chapter 11 – Upscaling and GMP production of pharmaceutical drug delivery systems. In: Shegokar RBT-DDT, ed. Elsevier; 2020:215-229. doi:https://doi.org/10.1016/B978-0-12-817870-6.00011-0

Image by Julia Teichmann from Pixabay