Filtration

Filtration

In the last installment of this short-lived but wildly-popular series, we’re going to talk a little bit about filtration: how to filter out all that bad energy, change that color up, and replace it with good vibes. We’ll talk about what filtration accomplishes and some different things it might do.

Filtration

verb: Filter

Many of the technical features and details concerning potential chemical/industrial advances in filtration were written about last month. So let’s filter the topic instead.

Remember winterization? The fats precipitating and agglutinating? Its after product looks like some combination of sour milk and a protein shake you forgot in the back of the fridge, depending on the winterization technique used. Lucky for us, the final product we want is the liquid all those gobs are floating around in. And we separate them by filtration.

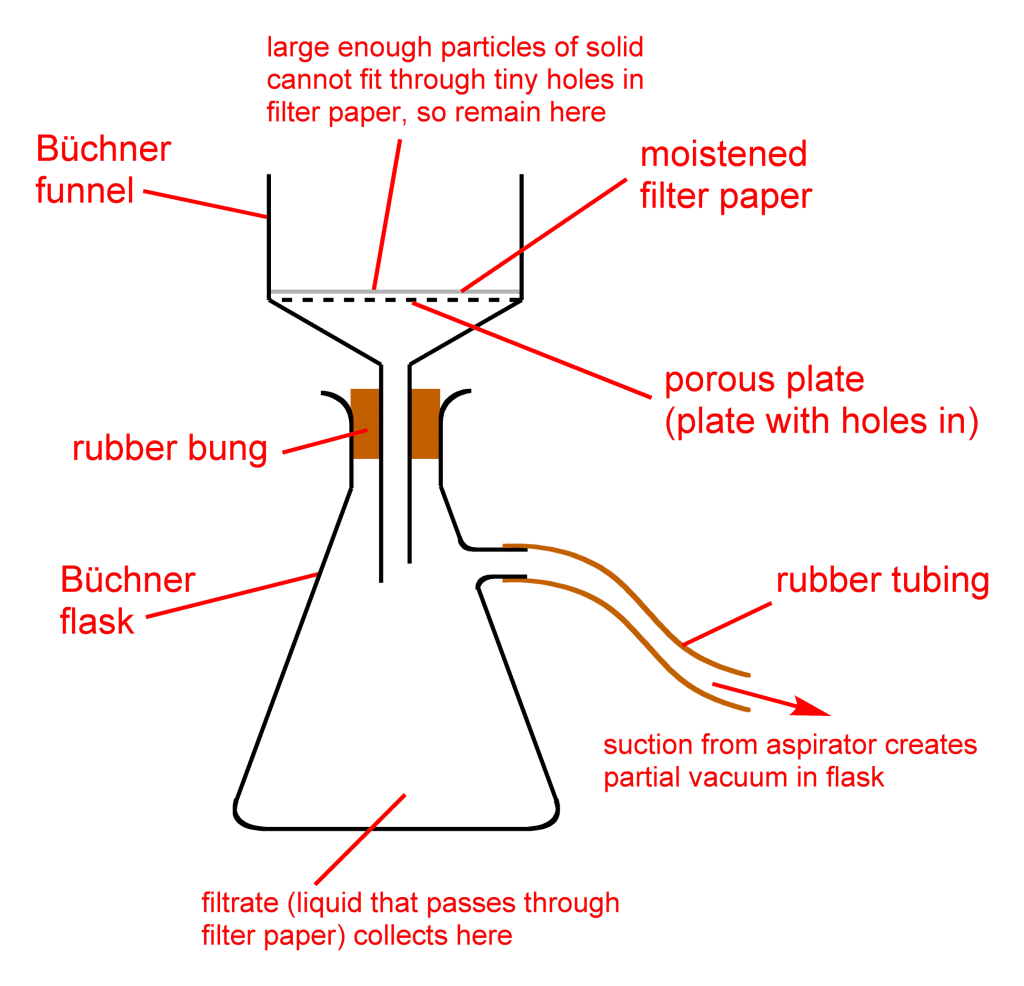

This step of cannabis extraction is, generally speaking, a fairly simple one. Successful filtration could be accomplished with as little as a small vacuum pump, vacuum flask, and Büchner funnel.

With the winterized extract still cold, you slowly pour the emulsion into the funnel with the vacuum on, then wait until the liquid level has gone down enough that you can pour in some more. Rinse, repeat. And generally speaking, the stronger the vacuum and the bigger that funnel, the more product you can run through it.

The one caveat worth mentioning is the filter paper. Much like a coffee filter, the filter paper is what will catch those solid fat particles as the liquid (now called the “filtrate”) drains through. There are many different types of filter paper, and besides the shape they’re cut or pressed into, their defining feature is their pore size, i.e., what size particles they’ll let through.

A busy lab will go through lots and lots of filter paper. The larger the pore is, the faster the filtration will go, because there’s just more surface area for the liquid to escape through. On the other hand, a pore too small will cause particles to clog the paper up too quickly, and your filtration will slow to a crawl. Striking the right balance in pore size will depend on the specifics of your equipment, the purity you are searching for, and the quality of your downstream distillation post-processing.

Filtration

Filtration