Cannabis’s Call to Microbrew Extracts

Many of us are beer fans, myself included. And no one has been more excited about the rise of the microbrewing industry than me (or maybe Jason). I’ve even attempted to brew a batch or two on my own. It wasn’t the best beer I’ve ever had, but it tasted decent, and more importantly, it was mine. There is a certain pride and joy that comes with making your own brews and sharing them with your family and friends. And while it may not be as easy or cheap as brewing your own beer, there may be a similar opening for a cannabis microbrewing industry to grow too.

Making solvent-based extracts at home, particularly with the use of hydrocarbon solvents, has come under scrutiny in recent years, because of the safety hazards involved and the residual solvent left behind. Presented here is the Soxhlet extraction, a solvent-based extraction method that’s been tried and true for over a century for removing compounds from plant and fruit matrices, both lipid-based and water-soluble. In this case, the solvent of choice is ethanol, and the plant—why cannabis, of course.

The Soxhlet apparatus was developed in the 1870’s by German chemist Franz Ritter von Soxhlet (1848–1926). He worked in the dairy industry, and originally developed the procedure (and glassware) as a means to separate cream (milk fat) from curds (solid protein formations). The apparatus was further refined with the invention of Pyrex, a borosilicate-based glass matrix, which created tougher, more resilient laboratory equipment.1 Interest fact: the “Py” in Pyrex comes from “apple pie”—the first Pyrex product! A picture of a Pyrex Soxhlet extractor from the early 20th century, courtesy of the Smithsonian Museum of American History, is shown below.

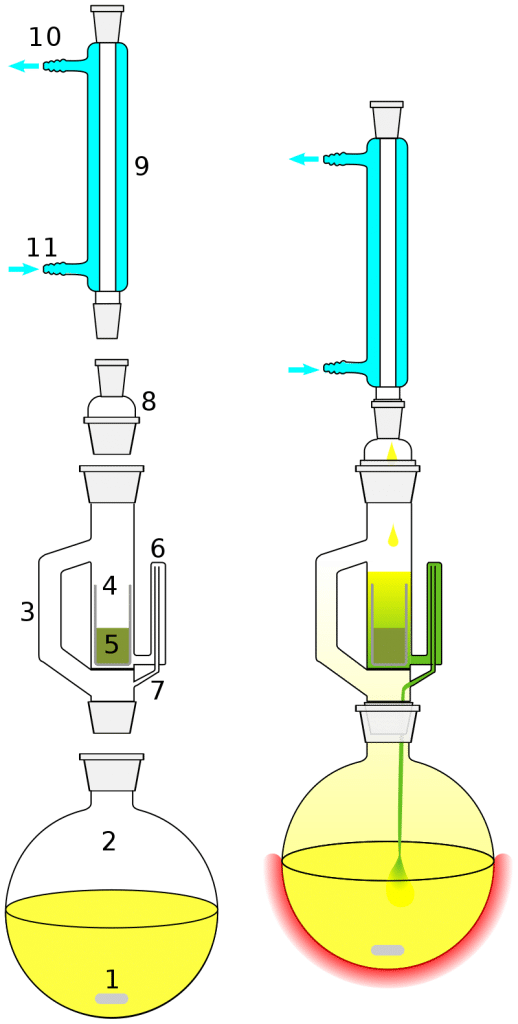

The way a Soxhlet extraction works is quite ingenious. First, a porous plug that won’t dissolve in the solvent (usually sterile cotton fiber) is placed at the bottom of the thimble [4]. This prevents solid components from being carried along, allowing for the desired separation of compounds. Cannabis flower is then loaded into the thimble on top of the first plug and packed fairly tight—the technique works best if the flower is ground beforehand, homogenizing the size of the particles and maximizing penetration of solvent into the plant. Then, cap the flower with a second porous plug to a depth of about 1”, depending on the size of your glassware. An alternative packing method is to prepare small volumes of homogenized flower in individual bags with appropriately small pores to contain the solid products, and pack these bags from the bottom of the thimble to the top.

A condenser [9] is added to the setup, with cold water flowing in from the bottom [11] and out from the top [10], the counter-current maximizing thermal exchange at the point closest to the Soxhlet glassware, reducing condensation time. Then, 95% ethanol (or higher) is added to the still pot [2]. A recent paper examining the THC content in nutritional hemp seeds described a Soxhlet extraction using 100-150 mL of ethanol for every gram of solid matrix.2

When the steps above are completed, a magnetic stirrer [1] is added to the still pot to evenly distribute heat and to avoid splashing bubble formation. Then, the still is lowered onto a specially-designed round-bottom heating mantle, which can also control the rate of stirring of the magnet. An example of what such a heating mantle looks like can be seen in the image below.

The ethanol is heated until reaching reflux, a steady-state of evaporation-condensation. When the heated ethanol reaches its boiling point, entering the gas phase, it travels up the distillation arm [3] until reaching the condenser, where it liquifies due to the cold temperature of the condenser walls. The liquid ethanol drips directly onto the thimble, enveloping and extracting any soluble components from the cannabis plant.

The key moment that makes the Soxhlet extraction special happens when enough ethanol has condensed so that the volume of liquid in the thimble reaches the height of the siphon top [6]. At that point, the physics behind siphon mechanics cause all the liquid in the thimble to drain through the siphon exit [7] and back into the still pot, leaving a thimble empty of liquid behind. Put all this together by following this link to see a crude animation of a working Soxhlet extractor.

Each cycle of solvation-extraction removes progressively more soluble compounds, and the more cycles that are allowed to occur, the more complete the extraction becomes. The aforementioned study on THC in hemp seeds described leaving the Soxhlet extraction under reflux for four hours.2

The main advantages of the Soxhlet technique is that one can achieve a very thorough full-spectrum extract with minimal loss of solvent, and without hands-on engagement with the equipment during the extraction phase. Key disadvantages are lower efficiency in the sense of the relatively long time the technique requires to extract from a relatively small amount of cannabis, and the accumulation of plant components soluble in ethanol, like chlorophyll, which affect extract taste and texture. The relatively higher temperature of this technique may also lead to some thermal degradation of desired products. And it’s important to note that, as with any solvent-based extraction, some amount of post-processing will need to occur, the exact processes depending on the final product in mind.

We are, however, optimistic. While this technique does not allow for scale-up, it provides a means for a culture of micro-brewed extracts to grow, similar to that seen in the beer industry. If individuals and small businesses find the capability to create their own extracts on a financial and time scale appropriate for their wishes, and are allowed to do so by legislative support, we may find ourselves living in a time where friends share extracts they’ve made at home much like they share home-brewed beers, with all the pride and joy that comes along with it. The Soxhlet extraction provides a feasible possibility for this to occur, with a relatively small investment in equipment, expertise, and time.

References

- Kraissl, F. “A history of the chemical apparatus industry”. J Chem Educ. 1933; 10(9): 519-523 [Times cited = 2, Journal impact factor = 1.758].

- Yang, Y. et al. “Cannabis sativa (Hemp) Seeds, Δ9-Tetrahydrocannabinol, and Potential Overdose”. Cannabis Cannabinoid Res. 2017; 2(1): 274–281 [Times cited = 7, Elsevier CiteScore = 3.1].

Image Credit: Wikimedia Commons